10 月 . 07, 2024 14:42 Back to list

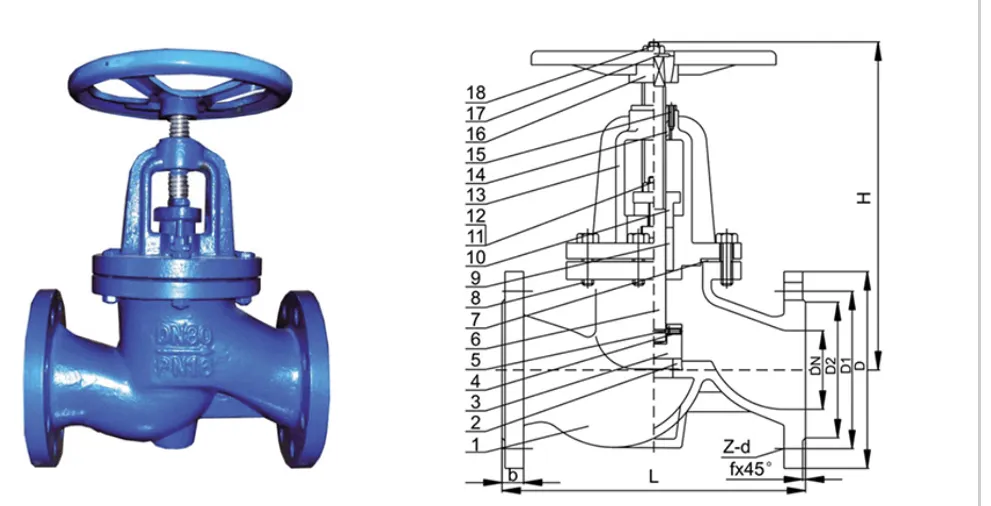

industrial globe valve

Understanding Industrial Globe Valves A Comprehensive Overview

Industrial globe valves are critical components in a variety of piping systems, utilized across numerous industries, including oil and gas, chemical manufacturing, water treatment, and power generation. Their main function is to regulate flow, which they achieve through a spherical body design and a movable plug or disk that can be lifted or lowered into the flow path.

The design of a globe valve enables it to perform exceptionally well in throttling applications. Unlike gate valves, which are primarily used for on-off service, globe valves allow for precise control of fluid flow. This is achieved through their unique internal structure, where the fluid path is angled, resulting in more turbulence but enabling better modulation of flow rates.

When selecting a globe valve for industrial applications, several factors must be considered. These include the valve size, material, pressure rating, and the specific properties of the fluid being controlled. Common materials for globe valves include stainless steel, carbon steel, and various alloys, each chosen based on factors like temperature, pressure, and chemical compatibility.

industrial globe valve

One of the advantages of industrial globe valves is their robust construction, which contributes to their longevity and reliability in demanding environments

. They can handle high-pressure applications and are available in various configurations, including threaded, flanged, and weld-end types. Their versatility makes them suitable for a range of fluids, from water and steam to corrosive and viscous substances.However, industrial globe valves do have some limitations. Their design typically results in a higher pressure drop compared to other valve types, such as ball valves. This can lead to increased energy costs in systems where high flow rates are necessary. Additionally, the internal components of globe valves can make them more susceptible to wear over time, particularly in applications involving abrasive materials.

In summary, industrial globe valves are essential for flow regulation in various industrial processes. Their unique design and construction allow for precise control, making them invaluable in applications requiring reliable and accurate flow management. When selecting a globe valve, it's crucial to consider the specific requirements of the application to ensure optimal performance and longevity. Understanding the characteristics and operational mechanisms of globe valves can lead to better decision-making and enhanced efficiency in industrial systems.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024