10 月 . 12, 2024 17:26 Back to list

industrial gate valve

Understanding Industrial Gate Valves A Comprehensive Overview

Gate valves are a critical component in various industrial applications, offering a simple yet effective way to control fluid flow. They are predominantly used in systems where a straight-line flow of fluid and minimum restriction is desired. This article delves into the functionality, design, applications, and advantages of industrial gate valves.

What is a Gate Valve?

Gate valves are linear motion valves that utilize a sliding gate to allow or stop fluid flow. Unlike other types of valves, such as globe or ball valves, gate valves are designed to be either fully open or fully closed. When open, the gate retracts into the valve body, providing a straight path for the fluid to flow, which minimizes pressure drop and resistance.

Design and Construction

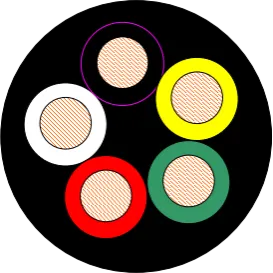

Industrial gate valves are generally constructed from durable materials such as cast iron, stainless steel, or carbon steel, which enhance their longevity and performance in harsh operating environments. The primary components of a gate valve include the body, gate, stem, and bonnet.

1. Body The valve body houses the internal components and provides the structural integrity of the valve. 2. Gate The gate can take various shapes, including wedge or paralel, which determines how the valve opens and closes. 3. Stem The stem connects the gate to the handle or actuator, allowing for movement. 4. Bonnet The bonnet is the cover that provides access to the internal components, especially useful for maintenance or repairs.

Industrial gate valves typically feature either manual or automated actuation mechanisms. Manual valves may have a handwheel for operation, while automated valves use electric or pneumatic actuators, enhancing the efficiency and control in large-scale operations.

industrial gate valve

Applications of Industrial Gate Valves

Gate valves are versatile in their applications. They are commonly found in various industrial sectors, including

- Oil and Gas Used in pipelines and refineries, gate valves facilitate the control of large volumes of fluids. - Water Supply and Wastewater Treatment In municipal water systems, gate valves help manage the flow and pressure. - Chemical Processing In this sector, they regulate the flow of corrosive substances, serving both safety and operational efficiency. - Power Generation Gate valves are essential in steam and cooling water systems within power plants.

Advantages of Using Gate Valves

1. Minimal Pressure Drop Gate valves provide a reduced flow resistance compared to other valve types, leading to enhanced operational efficiency. 2. Durability Made from high-quality materials, gate valves can withstand harsh conditions, making them suitable for long-term use in industrial applications. 3. Simple Operation With their straightforward design, gate valves are easy to operate, allowing for quick and efficient fluid control. 4. Full Flow Area When fully opened, gate valves offer a broad flow path, reducing turbulence and energy loss in fluid systems.

Conclusion

Industrial gate valves play a crucial role in fluid control across numerous sectors. Their design, which combines simple mechanics with robust construction, ensures that they can effectively manage flow while minimizing pressure drops and operational risks. For industries relying on the precise control of fluids such as oil, gas, water, and chemicals, employing the right gate valve is vital for maintaining system efficiency and safety. As technology progresses, innovations in gate valve design and actuation will likely continue to enhance their usability and reliability in industrial applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024