10 月 . 10, 2024 12:29 Back to list

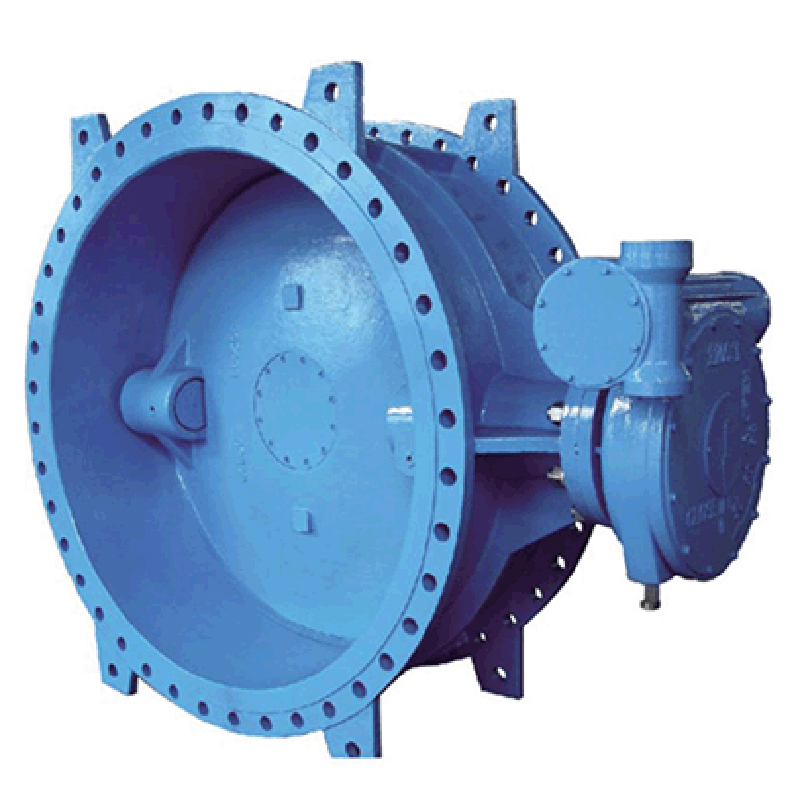

industrial gate valve

The Importance of Industrial Gate Valves in Modern Applications

Industrial gate valves are crucial components in many sectors that involve fluid control and transportation. These robust devices serve as essential mechanisms for regulating the flow of liquids and gases in various industrial processes. With their simple design and reliable operation, gate valves provide a dependable method to manage the passage of substances in pipelines.

Understanding Gate Valves

Gate valves are designed to start or stop the flow of fluids rather than to regulate it. When fully open, a gate valve offers minimal resistance to fluid flow, making it an ideal choice for applications where the pressure drop must be kept to a minimum. The mechanism operates through a wedge-shaped gate that lifts out of the path of the fluid, allowing for unobstructed flow.

One of the primary advantages of using gate valves is their ability to achieve a full flow, which is essential in large-scale operations. They can handle high pressure and are built from a variety of durable materials, including metals like stainless steel, carbon steel, and brass. The choice of material often depends on the specific application, including factors such as temperature, pressure, and the nature of the fluid being transported.

Applications Across Various Industries

Gate valves are used in a myriad of industries, including oil and gas, water treatment, power generation, petrochemicals, and manufacturing. In oil and gas, for instance, these valves can be employed in pipelines to control the flow of crude oil or natural gas, ensuring that the transportation processes are both efficient and safe.

In water treatment facilities, gate valves play a crucial role in managing the distribution of water. They can be utilized for isolating sections of a pipeline for maintenance or repair, ensuring that operations can continue smoothly with minimal interruptions. The versatility of gate valves makes them a preferred choice for many operations requiring reliable control of fluid dynamics.

Advantages of Gate Valves

industrial gate valve

1. Minimal Pressure Drop The design of gate valves allows fluids to flow through with minimal resistance when fully opened. This feature is particularly beneficial in applications where maintaining high flow rates is necessary.

2. Durability Gate valves are engineered to withstand adverse operating conditions, including high pressures and corrosive environments. Their sturdiness ensures a long lifespan, reducing the frequency of replacements and maintenance.

3. Cost-Efficiency Due to their reliability and low maintenance requirements, gate valves can be a cost-effective solution for companies. The initial investment is often mitigated by the longevity and performance of the valves.

4. Wide Range of Sizes and Standards Gate valves come in a variety of sizes, making them suitable for both large and small applications. They can also be manufactured according to international standards, ensuring compatibility with existing systems.

Considerations When Selecting Gate Valves

When choosing the right gate valve for a specific application, several factors must be considered. The type of fluid, its temperature and pressure, and the frequency of operation are critical aspects to evaluate. Additionally, the choice between rising stem and non-rising stem designs can impact the installation and maintenance of the valve.

It is also important to consider the potential for cavitation, especially in high-pressure applications. Cavitation can occur when there are rapid changes in pressure, leading to the formation of vapor bubbles that may collapse and cause damage to the valve. Proper sizing and selection are thus essential to prevent such issues.

Conclusion

In conclusion, industrial gate valves are indispensable in the modern industrial landscape. Their ability to provide effective flow control while minimizing pressure drop makes them a vital component in various industries. As technology continues to evolve, gate valves will likely adapt, incorporating innovative designs and materials to meet the growing demands of industrial applications. For companies looking to enhance their operations and maintain efficiency, understanding and implementing the right gate valve solutions is paramount.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024