11 月 . 03, 2024 15:00 Back to list

hydraulic check valve price

Understanding Hydraulic Check Valve Prices

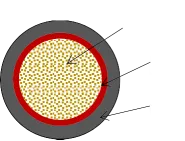

When it comes to hydraulic systems, safety and efficiency are paramount. One critical component in these systems is the hydraulic check valve. Its main function is to allow fluid to flow in one direction while preventing backflow, which ensures the smooth operation of hydraulic machinery. However, anyone looking to implement or replace a check valve must consider the costs involved. This article delves into the factors that influence hydraulic check valve prices and what users can expect.

Factors Influencing Price

1. Material Composition Hydraulic check valves are made from various materials such as brass, stainless steel, and polymer. The choice of material greatly affects the price. Stainless steel valves tend to be more expensive due to their durability and corrosion resistance, making them suitable for harsh environments and high-pressure applications. In contrast, brass valves are often more affordable but may not perform as well under extreme conditions.

2. Size and Specification Hydraulic check valves come in a range of sizes, with larger valves generally costing more due to the increased material requirements and potential manufacturing complexity. The specifications, such as pressure ratings and flow capacities, also play a critical role in determining the price. High-performance valves designed for specific applications may command a premium.

hydraulic check valve price

3. Type of Check Valve There are several types of hydraulic check valves, including ball, spring-loaded, and silent check valves. Each type serves different operational purposes and boasts unique design features, influencing their price. For example, silent check valves are designed to minimize water hammer and are typically more expensive than standard designs.

4. Brand and Quality Like many industrial components, the price of hydraulic check valves can vary based on the manufacturer. Well-established brands often charge more because of their reputation for quality and reliability. Investing in a trusted brand can lead to long-term savings by reducing maintenance needs and enhancing system performance.

5. Market Trends The global market for hydraulic components is dynamic, with prices affected by supply and demand, changes in material costs, and geopolitical factors. Those looking to purchase valves should stay informed about current market trends, as prices can fluctuate significantly.

Conclusion

The price of hydraulic check valves varies widely based on factors such as material, size, type, brand, and market conditions. As a component vital to the reliability of hydraulic systems, investing in a quality valve is essential. While it may be tempting to opt for the cheapest option available, considering long-term performance and durability can lead to better outcomes and cost-effectiveness. Ultimately, when purchasing hydraulic check valves, it’s crucial to balance cost with quality to ensure the stability and efficiency of your hydraulic systems.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024