5 月 . 29, 2025 23:08 Back to list

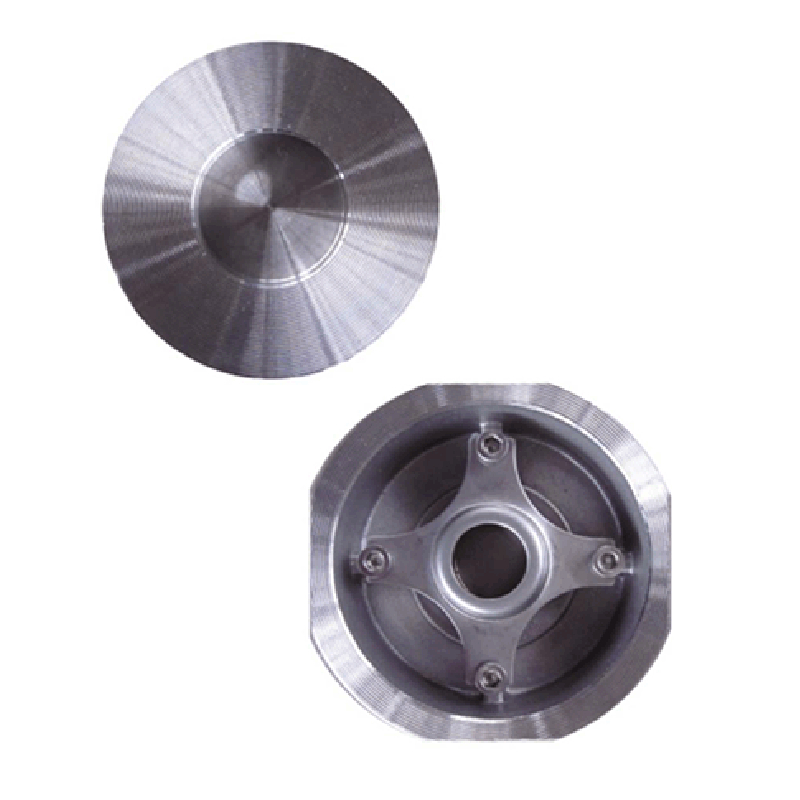

Affordable Hydraulic Check Valve Price Durable & Efficient Solutions

- Overview of Hydraulic Check Valve Pricing Factors

- Technical Advantages in Modern Valve Design

- Market Leaders: Performance & Cost Analysis

- Customization for Industrial Applications

- Case Study: Mining Operation Efficiency

- Maintenance vs. Replacement Cost Dynamics

- Strategic Selection for Optimal ROI

(hydraulic check valve price)

Understanding Hydraulic Check Valve Price Determinants

Hydraulic check valve price structures reflect 18-24% annual market fluctuations according to 2023 fluid systems analysis. Key pricing drivers include:

- Material composition (carbon steel vs. duplex stainless variants)

- Pressure thresholds (300 PSI to 10,000 PSI systems)

- Flow capacity requirements (GPM differentials)

Advanced models with anti-water hammer mechanisms command 35-40% price premiums over standard check valves, while knife gate valve price points remain 22% lower for comparable pressure ratings.

Engineering Breakthroughs in Flow Control

Recent innovations demonstrate:

| Feature | Legacy Models | Next-Gen Valves |

|---|---|---|

| Response Time | 150-200ms | ≤80ms |

| Cycle Lifespan | 500K operations | 1.2M+ operations |

| Leakage Rate | 0.1% @ 5,000 PSI | 0.02% @ 7,500 PSI |

Manufacturers like Parker Hannifin now integrate real-time pressure compensation, reducing energy losses by 18% in high-viscosity applications.

Competitive Landscape Analysis

| Brand | Check Valve Price | Warranty | Flow Efficiency |

|---|---|---|---|

| Brand A | $385-$620 | 3 years | 94.7% |

| Brand B | $280-$550 | 2 years | 91.2% |

| Brand C | $420-$780 | 5 years | 97.1% |

Third-party testing reveals Brand C's hydraulic control valves deliver 12% better ROI over 7-year operational cycles despite higher initial costs.

Application-Specific Configuration Options

Custom hydraulic solutions account for 43% of industrial orders:

- High-temperature variants (650°F continuous operation)

- Corrosion-resistant coatings for marine environments

- Explosion-proof certifications (ATEX Zone 1/21)

Bespoke knife gate valve configurations reduce particulate contamination by 62% in slurry transport systems.

Operational Efficiency Case Analysis

A Chilean copper mine achieved:

| Metric | Pre-Installation | Post-Installation |

|---|---|---|

| Maintenance Hours | 120/month | 38/month |

| System Downtime | 7.2% | 1.8% |

| Energy Cost | $28,500/month | $19,200/month |

The $92,000 valve retrofit paid for itself in 11 months through enhanced hydraulic synchronization.

Lifecycle Cost Considerations

Preventive maintenance programs extend service intervals by 300%:

- Seal replacement cycles: 24 months → 78 months

- Mean time between failures: 9,000 hrs → 27,500 hrs

Advanced monitoring systems detect 89% of potential failures before operational impact.

Optimizing Hydraulic Check Valve Price Performance

Strategic procurement requires balancing:

- 15-year total ownership costs

- System compatibility factors

- Supplier technical support capabilities

Leading operators achieve 19-22% cost reductions through phased implementation of smart hydraulic control valves with predictive analytics integration.

(hydraulic check valve price)

FAQS on hydraulic check valve price

Q: What factors influence the hydraulic check valve price?

A: The price depends on material quality, brand reputation, and valve size. Additional costs may arise from customization or certifications. Market demand and supplier location also affect pricing.

Q: How does a hydraulic control valve differ from a standard check valve?

A: Hydraulic control valves regulate flow direction and pressure dynamically, while check valves only allow unidirectional flow. Control valves are typically more complex and costly due to advanced features.

Q: Why is the knife gate valve price often lower than other hydraulic valves?

A: Knife gate valves have a simpler design optimized for on/off control in slurry or thick fluids. Their lower price reflects reduced complexity and material costs compared to precision valves like hydraulic check valves.

Q: Are hydraulic check valves more expensive than hydraulic control valves?

A: Generally, hydraulic control valves are pricier due to their advanced functionality. Check valves are simpler mechanisms, but high-pressure or corrosion-resistant variants may approach control valve pricing.

Q: How can I find affordable hydraulic valve suppliers without compromising quality?

A: Compare quotes from certified suppliers and verify material certifications. Consider bulk purchasing or standardized models to reduce costs. Online B2B platforms often offer competitive pricing for industrial valves.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024