10 月 . 04, 2024 02:36 Back to list

grooved end butterfly valve

Grooved End Butterfly Valve A Comprehensive Overview

The grooved end butterfly valve is an essential component in modern piping systems, widely utilized in various industries such as water treatment, oil and gas, and HVAC applications. Renowned for its reliability and efficiency, this type of valve is designed to control the flow of fluids through a pipeline sustainably.

Design and Construction

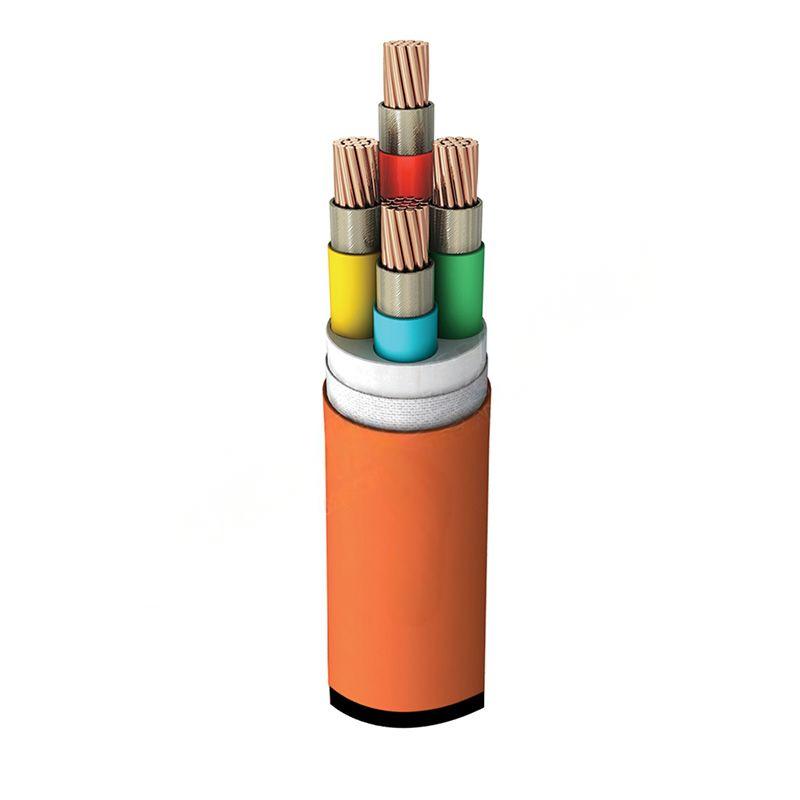

The distinctive feature of the grooved end butterfly valve is its grooved ends, which are designed for easy installation and secure connections with piping systems. These grooves allow for a mechanical grip when paired with compatible grooved fittings, eliminating the need for welding or thread connections. This not only speeds up installation but also ensures a leak-tight seal, making it an ideal choice for low-pressure applications.

The valve consists of a circular disc that rotates around a central axis. When the disc is perpendicular to the flow, the valve is closed, stopping the fluid flow. Conversely, when the disc is parallel, the valve is open, allowing smooth fluid passage. The simplicity of this design contributes to low pressure drops, making grooved end butterfly valves an energy-efficient option.

Advantages

grooved end butterfly valve

One of the primary advantages of using grooved end butterfly valves is their lightweight construction, which makes handling and installation easier compared to heavier valve types. Additionally, their compact design allows for space-saving installations. These valves are also known for their versatility; they can be used in various applications and can handle a wide range of temperatures and pressures, depending on the materials used in their construction.

Maintenance is another benefit of grooved end butterfly valves. Their straightforward design means that they have fewer moving parts, which reduces wear and tear over time. This results in fewer maintenance requirements and extended service life, ultimately reducing operational costs.

Applications

Grooved end butterfly valves are used in a plethora of applications, from municipal water supply systems to industrial processes. In HVAC systems, they regulate airflow, while in the oil and gas industry, they control the flow of various fluids. Their adaptability makes them suitable for both commercial and residential applications.

Conclusion

In conclusion, grooved end butterfly valves stand out for their ease of use, reliability, and cost-effectiveness. Their design not only facilitates quick installation but also ensures optimal performance across diverse applications. As industries continue to prioritize efficiency and sustainability, the importance of reliable flow control solutions like the grooved end butterfly valve cannot be underestimated.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024