10 月 . 17, 2024 11:27 Back to list

Grooved End Butterfly Valve for Efficient Flow Control Solutions in Various Applications

Understanding Grooved End Butterfly Valves A Comprehensive Overview

Butterfly valves are widely recognized as essential components in various fluid control systems, particularly in the field of industrial piping. Among the numerous types of butterfly valves available, the grooved end butterfly valve stands out due to its unique design and practical application. This article delves into the characteristics, advantages, and applications of grooved end butterfly valves.

What is a Grooved End Butterfly Valve?

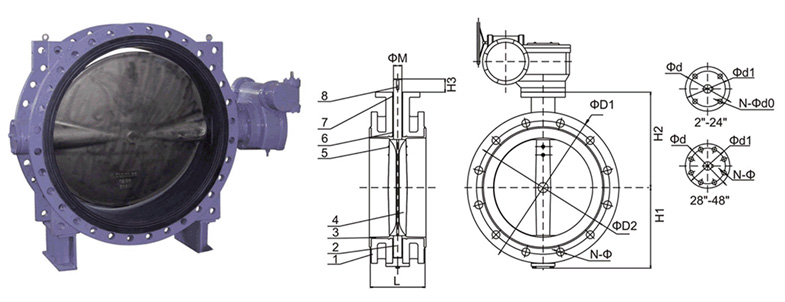

A grooved end butterfly valve is a type of quarter-turn valve that uses a flat circular disc as its primary mechanism. The disc rotates to open or close the flow path, enabling or blocking fluid flow through the pipeline. The grooved end refers to the valve's connection feature, which incorporates grooves on the ends of the valve body. These grooves facilitate the use of grooved piping systems, allowing for a more adaptable and secure installation.

Key Features

1. Design and Mechanics The grooved end butterfly valve consists of a valve body, disc, stem, and actuator. The grooved design allows for quick and easy installation without the need for welding or additional fittings. The valve operates through a simple quarter-turn mechanism, providing rapid access to flow control.

2. Materials Grooved end butterfly valves can be manufactured from various materials, including ductile iron, stainless steel, and PVC. The choice of material depends on the intended application, operating environment, and the nature of the fluids they will control.

3. Sizes and Variants These valves come in various sizes, diameters, and pressure ratings, making them suitable for an extensive range of applications. They can be fitted with different types of actuators, including manual, pneumatic, or electric options, enhancing their versatility.

Advantages of Grooved End Butterfly Valves

1. Easy Installation One of the most significant benefits of grooved end butterfly valves is their ease of installation. The grooved connections offer a quick and reliable method of attaching valves to piping systems, significantly reducing installation time and labor costs.

2. Space Efficiency Grooved end butterfly valves are compact, which allows them to be installed in limited spaces without sacrificing performance. Their design minimizes the overall footprint, making them ideal for systems with space constraints.

grooved end butterfly valve

3. Cost-Effectiveness The reduction in installation time and labor costs, combined with lower material needs, makes grooved end butterfly valves a cost-effective choice for fluid control systems. Their durability also translates to lower maintenance costs in the long run.

4. Robust Performance These valves are designed to handle a wide range of temperatures and pressures, making them suitable for numerous industrial applications. Their robust construction ensures reliable performance even in demanding environments.

Applications

Grooved end butterfly valves find extensive use across various industries. Some of the key areas of application include

1. Water and Wastewater Treatment In municipal water treatment facilities, these valves are employed to control the flow of water, ensuring efficient operation and maintenance.

2. HVAC Systems In heating, ventilation, and air conditioning systems, grooved end butterfly valves help regulate fluid flow, contributing to energy efficiency and system performance.

3. Chemical Processing The ability to handle corrosive fluids makes these valves suitable for chemical processing applications, where they control flow in pipelines transporting various chemicals.

4. Fire Protection Systems In fire protection, grooved end butterfly valves are used in sprinkler and standpipe systems, where reliable operation is crucial for safety.

5. Oil and Gas The energy sector uses these valves for pipeline applications, where their ability to withstand high pressures and temperatures is essential.

Conclusion

In summary, grooved end butterfly valves represent an innovative solution for effective fluid control in various applications. Their ease of installation, robust performance, and versatility make them a preferred choice in many industries. As technology continues to evolve, grooved end butterfly valves will likely remain integral to fluid management systems, adapting to new challenges and opportunities in the market. Understanding their features and applications is essential for engineers, contractors, and procurement professionals looking to enhance their systems’ efficiency and reliability.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024