2 月 . 10, 2025 22:51 Back to list

Portable Cord

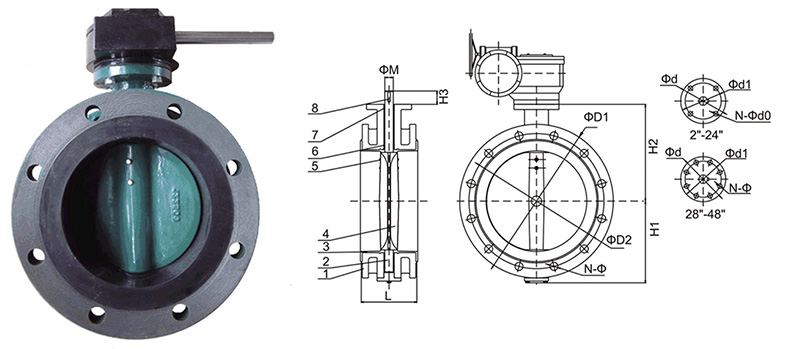

Grooved butterfly valves have become indispensable components in various industries, providing an efficient and reliable means of regulating flow in piping systems. Their unique design distinguishes them from other types of valves, offering distinct advantages that align with the needs of evolving industries such as water treatment, oil and gas, HVAC, and more.

In seismic or high-vibration settings, such as those found in industrial machinery or earthquake-prone areas, grooved butterfly valves enhance safety with their flexibility. The ability to absorb vibrations and allow for slight pipe movements without loss of sealing integrity is a testament to their engineering precision. This capability of maintaining operational security under duress further cements their authoritative role in ensuring safe environments. Furthermore, advanced technological integrations have allowed grooved butterfly valves to stay at the forefront of smart system implementations. Many are now offered with electronic actuation options that seamlessly integrate into automated system controls. By providing real-time data on valve positioning and system conditions, these valves become a smart piece of the puzzle in modern infrastructure, delivering experience-driven solutions tailored to complex operational needs. In educational settings and professional training, grooved butterfly valves are often showcased due to their sophisticated yet comprehensible design. They serve as an exemplary teaching tool on fluid dynamics principles and efficient system management, reinforcing the trustworthiness and enduring relevance of these components in technical advancement. In conclusion, grooved butterfly valves represent a blend of innovative design, unmatched reliability, and forward-thinking adaptability. Their role across various sectors underscores a commitment to efficiency and integrity, demonstrating professional excellence and earning the trust of industries worldwide. This embodies the critical qualities — experience, expertise, authoritativeness, and trustworthiness — that define high-performing products in today’s competitive market.

In seismic or high-vibration settings, such as those found in industrial machinery or earthquake-prone areas, grooved butterfly valves enhance safety with their flexibility. The ability to absorb vibrations and allow for slight pipe movements without loss of sealing integrity is a testament to their engineering precision. This capability of maintaining operational security under duress further cements their authoritative role in ensuring safe environments. Furthermore, advanced technological integrations have allowed grooved butterfly valves to stay at the forefront of smart system implementations. Many are now offered with electronic actuation options that seamlessly integrate into automated system controls. By providing real-time data on valve positioning and system conditions, these valves become a smart piece of the puzzle in modern infrastructure, delivering experience-driven solutions tailored to complex operational needs. In educational settings and professional training, grooved butterfly valves are often showcased due to their sophisticated yet comprehensible design. They serve as an exemplary teaching tool on fluid dynamics principles and efficient system management, reinforcing the trustworthiness and enduring relevance of these components in technical advancement. In conclusion, grooved butterfly valves represent a blend of innovative design, unmatched reliability, and forward-thinking adaptability. Their role across various sectors underscores a commitment to efficiency and integrity, demonstrating professional excellence and earning the trust of industries worldwide. This embodies the critical qualities — experience, expertise, authoritativeness, and trustworthiness — that define high-performing products in today’s competitive market.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024