9 月 . 06, 2024 22:45 Back to list

Grooved End Butterfly Valve - Durable, Reliable, and Efficient

The Grooved End Butterfly Valve A Comprehensive Overview

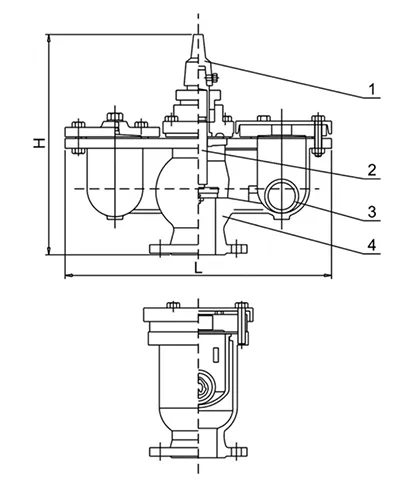

The grooved end butterfly valve is an essential component widely utilized in various industries for fluid regulation and control. This valve design is particularly favored for its simplicity, lightweight structure, and efficiency in managing flow within pipes. Butterfly valves, in general, feature a disc that rotates on a shaft to either allow or obstruct flow, making them an ideal choice for quick shut-off applications.

One of the standout features of the grooved end butterfly valve is its unique connection method. Unlike traditional flanged connections, grooved end designs utilize grooves that allow for a more secure and flexible attachment to piping systems. This feature significantly simplifies installation and maintenance, as it eliminates the need for complicated flanges and bolting systems. Grooved ends also enable the use of couplings, which further enhance the ease of assembly and disassembly during maintenance or repairs.

The grooved end butterfly valve is constructed from various materials, including cast iron, stainless steel, and plastic, making it adaptable for numerous applications

. Its wide material selection allows it to withstand different pressures, temperatures, and corrosive environments. For instance, stainless steel variants are commonly used in food and beverage industries due to their hygiene standards and resistance to corrosion.grooved end butterfly valve

In terms of functionality, the grooved end butterfly valve offers quick and efficient operation. The design allows for smooth operation with minimal torque compared to other valve types, which often results in reduced wear and tear on the actuator. This efficiency is critical in dynamic processes such as water treatment, HVAC systems, and chemical processing where responsiveness is key.

Aside from operational benefits, the grooved end butterfly valve contributes to energy savings. The streamlined flow paths inherent in the valve design minimize turbulence and pressure drops, leading to lower energy consumption in pumping applications. This characteristic not only aids in operational costs but also supports environmental sustainability by reducing energy waste.

Installation versatility also plays a critical role in the popularity of grooved end butterfly valves. They can be installed in various orientations—vertical, horizontal, or anywhere in between—providing flexibility in system design. Additionally, these valves can be equipped with various actuator options, including manual handles, electric, and pneumatic actuators, catering to diverse operational needs.

In conclusion, the grooved end butterfly valve stands out as a reliable and efficient choice for fluid control in numerous industrial applications. With its ease of installation, versatility, and operational efficiency, it continues to be a preferred option for engineers and system designers looking to optimize their fluid handling processes. As industries evolve, the importance of such efficient solutions will remain paramount, ensuring that the grooved end butterfly valve retains its significance in modern engineering applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024