11 月 . 01, 2024 05:49 Back to list

Understanding the Functionality of Groove Check Valves in Fluid Systems

Understanding Groove Check Valves Functionality and Applications

Introduction

In the realm of fluid control systems, groove check valves play a pivotal role in ensuring the proper flow of liquids and gases. These components are designed to prevent backflow in piping systems, a crucial factor in maintaining system integrity and efficiency. In this article, we will explore the functionality, types, and applications of groove check valves, highlighting their importance in various industries.

Functionality of Groove Check Valves

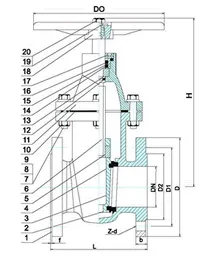

A groove check valve operates based on a simple yet effective design. It employs a disc or a ball that moves within the valve body to allow flow in one direction while preventing reverse flow. The groove refers to the feature used to ensure the proper seating of the disc when there is no flow. This design not only prevents backflow but also minimizes the risk of contamination in the system, making it essential for applications where fluid purity is paramount.

The primary function of a groove check valve is to facilitate the unidirectional flow of fluids. When fluid enters the valve from the inlet side, it pushes the disc upward, allowing the fluid to pass through. However, if there is any attempt for the fluid to flow back, the disc is pushed back into its seat, effectively sealing the valve and stopping reverse flow. This mechanism is crucial in various systems, including water supply systems, HVAC systems, and chemical processing plants.

Types of Groove Check Valves

There are several types of groove check valves, each designed to meet specific operational requirements. The most common types include

groove check valve

1. Swing Check Valves These valves use a swinging disc to allow or prevent flow. When fluid flows in the correct direction, the disc swings open, but it quickly closes when backflow occurs.

2. Lift Check Valves Instead of swinging, these valves feature a disc that lifts off its seat to permit flow. They are often used in applications with high flow rates and pressure variations.

3. Ball Check Valves These utilize a ball that sits in the valve body. When flow occurs, the ball is lifted, allowing the fluid to pass. If backflow attempts to occur, the ball rolls back into the seat, preventing reverse flow.

Applications of Groove Check Valves

Groove check valves are widely used across various industries due to their reliability and effectiveness. Some notable applications include

- Water Distribution Systems Preventing backflow in municipal water supplies to ensure clean drinking water. - Chemical Processing Safeguarding against contamination in chemical pipelines, ensuring the safety and purity of the substances being transported. - HVAC Systems Maintaining proper airflow and preventing backflow in heating and cooling systems. - Oil and Gas Industry Protecting equipment and pipelines from backflow, which could lead to dangerous situations and equipment failure.

Conclusion

Groove check valves are essential components in maintaining the integrity of fluid control systems. Their ability to prevent backflow ensures efficient operation and safety across a wide range of industries. With various types available, these valves can be selected to meet specific needs, making them a versatile choice for engineers and system designers. Understanding their functionality and applications is vital for anyone involved in the design and maintenance of fluid systems.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024