9 月 . 15, 2024 22:41 Back to list

groove check valve

Understanding Groove Check Valves Function and Applications

Groove check valves play a crucial role in various piping systems by ensuring the proper flow of fluids, preventing backflow, and maintaining system integrity. These valves are designed to allow fluid to flow in one direction while restricting reverse flow, which can lead to system malfunctions or damage. Their unique design and functionality make them an essential component in many industrial and commercial applications.

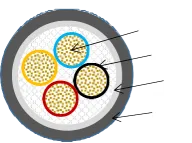

One of the defining features of groove check valves is their construction. Typically made from materials such as brass, stainless steel, or PVC, these valves boast a rugged build that can withstand high pressures and varying temperature conditions. The groove in the name refers to the specific groove design that facilitates easy installation and disassembly. This feature is particularly beneficial during maintenance, as it allows for quick access to the valve without needing to dismantle the entire piping system.

The operation of a groove check valve relies on the principle of hydrostatic pressure. When the fluid flows in the intended direction, it pushes against a movable disc or ball inside the valve, allowing flow to continue. However, if the flow attempts to reverse, the pressure drops, causing the disc or ball to seal against the seat of the valve, effectively blocking any backflow. This mechanism is crucial in systems where the integrity of the fluid flow is paramount, such as in irrigation, water supply systems, and various industrial processes.

groove check valve

One of the primary applications of groove check valves is in water supply systems

. These systems require reliable components to prevent contamination and ensure a clean supply of water. By promptly closing off any reverse flow, groove check valves help maintain pressure and protect the water quality, making them indispensable in municipal waterworks.In industrial applications, groove check valves are frequently utilized in systems involving chemicals or gases. The ability to contain and control the flow of potentially hazardous materials is a vital consideration in such environments. Using groove check valves, plants can enhance safety protocols and prevent accidents that may arise from backflow situations.

Moreover, groove check valves can be found in HVAC systems, where they help regulate the flow of refrigerants and maintain system efficiency. The interplay of pressure and fluid dynamics within these systems can lead to significant energy savings, highlighting the importance of reliable valve systems.

In conclusion, groove check valves are integral to many piping systems across various industries. Their ability to prevent backflow, combined with their easy installation and maintenance, makes them a preferred choice for engineers and maintenance professionals alike. As industries continue to evolve and demand more efficient and reliable systems, the role of groove check valves will undoubtedly remain significant, ensuring safe and effective fluid management in countless applications. By understanding their function and applications, stakeholders can make informed decisions that enhance system reliability and performance.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024