1 月 . 06, 2025 19:20 Back to list

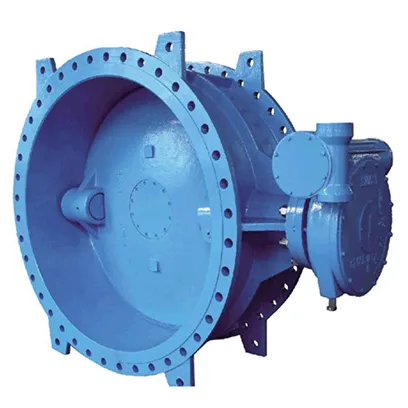

U Type Butterfly Valve

In the dynamic world of industrial hardware, gate valves hold a pivotal position, respected for their robust design and wide applicability across various sectors. As an expert in fluid control systems with over a decade of hands-on experience, I can attest to the indispensable nature of gate valves in complex pipeline configurations that necessitate precise flow regulation and minimal pressure loss.

One of the distinguishing attributes of gate valves is their ability to provide unobstructed flow with almost negligible pressure drop when fully open. This is particularly advantageous in applications where high volume flow and efficiency are paramount. Unlike some valve types that are limited by design to specific positions, gate valves offer the flexibility of on-off control, which is ideal for systems that require full shut-off capabilities. This operational versatility makes them a preferred choice in industries ranging from oil and gas to water treatment facilities.

Constructed typically from resilient materials such as stainless steel, cast iron, or bronze, gate valves are engineered to withstand harsh operational environments. Their ability to maintain integrity under high pressure and temperature conditions speaks volumes about their reliability, which is crucial for ensuring the safety and efficiency of industrial processes. In my professional practice, I've witnessed numerous instances where the correct selection and maintenance of gate valves have directly contributed to system longevity and operational cost savings.

Expertise in gate valves isn't just about understanding their construction and function, but also knowing when and where to implement them effectively. For example, in pipeline systems that transport corrosive materials, choosing a gate valve with corrosion-resistant coatings or made from special alloys can drastically reduce maintenance costs and prevent unexpected downtimes. This expertise enables engineers to design systems that are not only efficient but also resilient against the challenges posed by the materials being transported.

gate valve

Knowledge carries authority, and my extensive experience has shown me that gate valves are indispensable in applications requiring isolation with minimal leakage. Their robust sealing mechanisms often involve the use of elastomers or metal-to-metal sealing, capable of enduring cyclic operations. These design features underscore the importance of gate valves in critical installations such as power plants and chemical processing facilities, where reliability is non-negotiable.

Trustworthiness in recommendations is earned through proven results. Over the years, I've engaged with numerous case studies and client installations showcasing the long-term benefits of gate valve application. In collaborations with industry partners, implementing gate valves has consistently resulted in improved system performance, reduced energy consumption, and enhanced safety. These real-world outcomes provide a substantial foundation for trust, reinforcing the gate valve’s reputation as a stalwart component in fluid control systems.

In conclusion, the enduring utility of gate valves in industrial applications is backed by their ability to deliver consistent and reliable performance. Professionals seeking to optimize system efficiency must consider gate valves not just as a component, but as a strategic choice in fluid management. With evolving technological advancements, gate valves continue to adapt, offering sophisticated solutions that meet the rigorous demands of modern industry. Embracing these innovations with seasoned expertise assures not only current success but also future preparedness in the ever-evolving landscape of industrial systems.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024