9 月 . 16, 2024 06:40 Back to list

Galvanized Rubber Expansion Joint - Durable and Reliable Solutions

Galvanized Rubber Expansion Joints A Comprehensive Overview

In the world of industrial piping systems, the management of thermal expansion and contraction is crucial for maintaining system integrity and efficiency. Among the various solutions available, galvanized rubber expansion joints stand out due to their unique combination of flexibility, durability, and corrosion resistance.

An expansion joint is a device designed to absorb the movement resulting from thermal expansion or contraction, vibration, and mechanical movement within piping systems. Galvanized rubber expansion joints specifically incorporate a protective galvanized metal exterior, which enhances their resilience against environmental factors and corrosive substances. This feature makes them particularly useful in applications where exposure to moisture, chemicals, or extreme temperatures is a concern.

The core of a galvanized rubber expansion joint typically consists of layers of rubber, which provide excellent flexibility and are able to accommodate varying degrees of movement. This flexibility is essential in preventing stress on the pipes and associated equipment. As the temperature changes, the rubber within the joint can compress or elongate, absorbing the expansion and contraction without transferring excessive stress to the system. This capability not only enhances the longevity of the piping infrastructure but also minimizes the risk of leaks, cracks, or catastrophic failures.

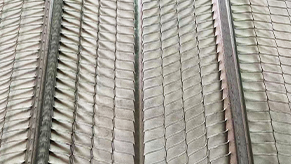

galvanized rubber expansion joint

Another significant benefit of galvanized rubber expansion joints is their ability to dampen vibrations. Industrial systems often generate vibrations due to the operation of pumps, compressors, or fans. These vibrations can lead to wear and tear on pipes and the surrounding structures. The rubber material within the expansion joint acts as a cushion, effectively isolating such vibrations and protecting the integrity of the entire system.

Installation of galvanized rubber expansion joints is relatively straightforward. They can be incorporated into existing systems without the need for extensive modifications. This ease of installation, coupled with their cost-effectiveness, makes them an attractive choice for engineers and maintenance personnel.

In terms of maintenance, these expansion joints require minimal intervention. Regular inspections and monitoring for signs of wear are usually sufficient to ensure they continue to perform effectively. If any degradation is noted, replacement can be done swiftly, further minimizing downtime for the system.

In conclusion, galvanized rubber expansion joints are essential components in modern piping systems. Their ability to manage thermal expansion, absorb vibrations, and resist corrosive elements makes them invaluable in a variety of industrial applications. By investing in high-quality expansion joints, companies can protect their infrastructure, reduce maintenance costs, and ultimately enhance overall operational efficiency.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024