10 月 . 11, 2024 09:00 Back to list

full lug butterfly valve

Understanding Full Lug Butterfly Valves Features and Applications

Full lug butterfly valves are essential components in various industrial applications, renowned for their robust construction and efficient performance in regulating flow. These valves are designed with a distinctive lug configuration, which provides added stability and strength when installed. The full lug feature allows the valve to be easily mounted between two flanges, making it a popular choice for both water and wastewater treatment, chemical production, and HVAC systems.

Design and Construction

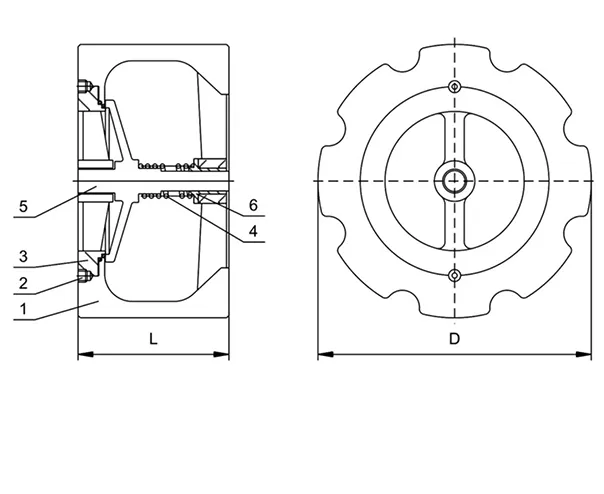

The design of a full lug butterfly valve features a disc that rotates around a central shaft, allowing for precise control of flow. The full lug aspect refers to the presence of lugs or protrusions on both sides of the valve body. These lugs enable the valve to be bolted directly to the flanges of the piping system, which enhances its ability to withstand high pressure and temperature variations. This design not only ensures secure installation but also provides ease of maintenance, as the valve can be removed without disturbing the pipeline.

Typically made from materials such as stainless steel, ductile iron, or PVC, full lug butterfly valves offer excellent corrosion resistance and durability. The choice of material often depends on the specific application and the type of media being controlled. Additionally, these valves can be fitted with various seal types, including elastomeric seals, PTFE, or metal seals, further enhancing their versatility and performance.

Advantages of Full Lug Butterfly Valves

One of the primary advantages of full lug butterfly valves is their lightweight construction, which makes them easy to handle and install. Unlike traditional gate or globe valves, butterfly valves require less space and can be installed in confined areas, making them ideal for retrofitting existing systems. Their simple design also leads to lower manufacturing costs, which can translate into savings for end-users.

full lug butterfly valve

Moreover, full lug butterfly valves provide excellent flow control characteristics. They can be fully opened or closed quickly with just a quarter turn, allowing for rapid response in processes that demand precise flow regulation. This efficiency is particularly beneficial in applications where energy conservation is crucial, such as in cooling systems or when managing fluid transfer in chemical plants.

Applications in Various Industries

The versatility of full lug butterfly valves makes them suitable for a wide array of industries. In the water and wastewater sector, they are commonly used for isolation and throttling purposes, helping manage the flow of treated and untreated water. In the chemical industry, these valves control the flow of aggressive media with their corrosion-resistant materials, ensuring safe and effective operations.

Additionally, HVAC systems utilize full lug butterfly valves to optimize airflow within ducts, promoting energy efficiency and temperature control. Their ability to handle high flow rates and varying pressure levels also makes them indispensable in power generation and oil and gas applications.

Conclusion

In conclusion, full lug butterfly valves are crucial components in modern industrial systems, combining efficiency, durability, and ease of installation. Their unique design and functionality make them a preferred choice across various sectors, ensuring reliable operations and effective flow control. As technology advances, the continued innovation in valve design will likely enhance their applications, making full lug butterfly valves an essential topic for engineers and operators alike.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024