1 月 . 15, 2025 09:17 Back to list

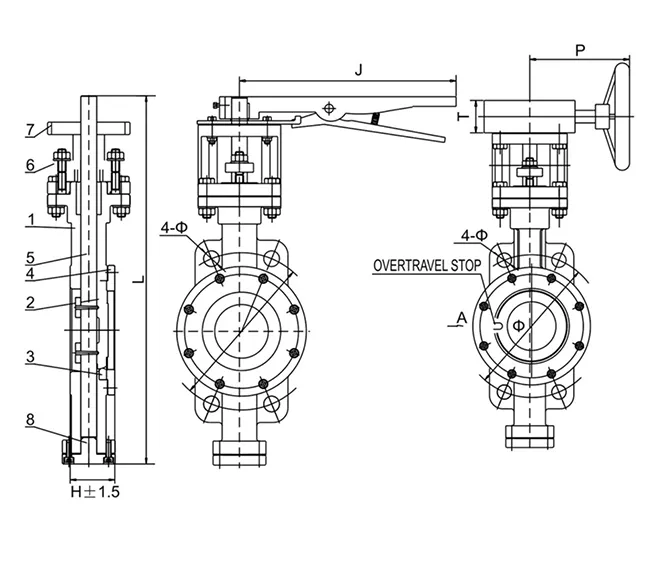

full lug butterfly valve

Full lug butterfly valves have emerged as an essential component in various industrial applications, offering unique benefits and versatility in fluid control systems. These valves are particularly popular for their robust design, reliability, and ease of installation and maintenance. Understanding the advantages and applications of full lug butterfly valves can enhance both the efficiency and lifespan of systems that rely on precise fluid control.

From a technical standpoint, the choice of materials in manufacturing full lug butterfly valves contributes to their effectiveness and longevity. Commonly used materials include stainless steel, ductile iron, and high-performance alloys, each offering distinct advantages depending on the specific application and environmental conditions. Stainless steel, for instance, provides exceptional resistance to corrosion and is favored in settings where hygiene and cleanliness are paramount. For system engineers and maintenance professionals seeking long-term reliability, the installation of full lug butterfly valves presents a cost-effective solution. They not only reduce the need for extensive pipe support due to their lightweight nature but also minimize pressure drop in the system, thereby conserving energy and reducing operational costs. In conclusion, full lug butterfly valves represent a fusion of engineering precision and practical functionality. Their design accommodates a myriad of industrial applications where fluid control is necessary, making them indispensable in modern engineering projects. When selecting the right valve, it's essential to consider the specific requirements of the application, including pressure ratings, material compatibility, and operational stability. Implementing full lug butterfly valves can vastly improve system performance, ensuring reliable fluid management while simultaneously reducing maintenance requirements. By leveraging the expertise and authority of leading valve manufacturers, industries can trust the durability and efficiency of this pivotal component in their fluid control infrastructure.

From a technical standpoint, the choice of materials in manufacturing full lug butterfly valves contributes to their effectiveness and longevity. Commonly used materials include stainless steel, ductile iron, and high-performance alloys, each offering distinct advantages depending on the specific application and environmental conditions. Stainless steel, for instance, provides exceptional resistance to corrosion and is favored in settings where hygiene and cleanliness are paramount. For system engineers and maintenance professionals seeking long-term reliability, the installation of full lug butterfly valves presents a cost-effective solution. They not only reduce the need for extensive pipe support due to their lightweight nature but also minimize pressure drop in the system, thereby conserving energy and reducing operational costs. In conclusion, full lug butterfly valves represent a fusion of engineering precision and practical functionality. Their design accommodates a myriad of industrial applications where fluid control is necessary, making them indispensable in modern engineering projects. When selecting the right valve, it's essential to consider the specific requirements of the application, including pressure ratings, material compatibility, and operational stability. Implementing full lug butterfly valves can vastly improve system performance, ensuring reliable fluid management while simultaneously reducing maintenance requirements. By leveraging the expertise and authority of leading valve manufacturers, industries can trust the durability and efficiency of this pivotal component in their fluid control infrastructure.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024