10 月 . 05, 2024 05:06 Back to list

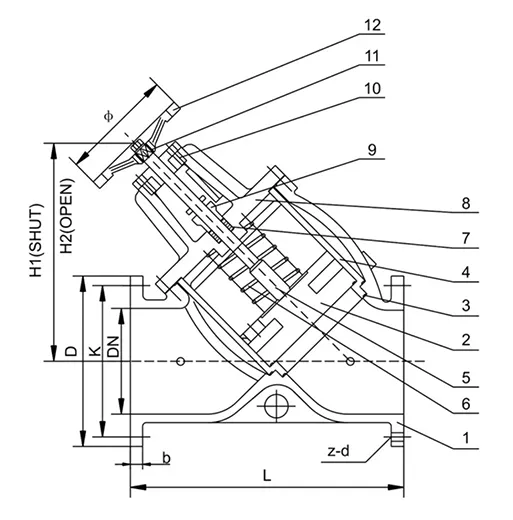

foot valve with strainer

Understanding the Foot Valve with Strainer A Key Component in Fluid Systems

In various fluid systems, particularly in water and wastewater management, the foot valve with strainer plays a crucial role in ensuring the efficient operation of pumps and preventing system failures. This article will delve into the fundamental aspects and benefits of foot valves with strainers, their design, applications, and maintenance considerations.

What is a Foot Valve?

A foot valve is a type of check valve that is typically installed at the bottom of a suction line of a pump. Its primary function is to maintain the prime in the pump by preventing backflow when the pump is not operational. This feature is essential in maintaining the efficiency and longevity of pumping systems.

The Role of Strainers

Integrated with the foot valve, a strainer serves as a protective filter that prevents debris and larger particles from entering the pump. This is particularly important because any foreign particles can cause significant damage to the pump impeller and other components, leading to inefficient operation and costly repairs. The strainer typically consists of a mesh screen with specific openings depending on the intended application.

How Does a Foot Valve with Strainer Work?

When a pump is operational, the foot valve opens, allowing fluid to be drawn into the pump. The strainer filters out any unwanted solids, ensuring that only clean fluid enters the pump. When the pump stops, the foot valve closes to prevent backflow, effectively keeping the pump primed and ready for the next cycle. This dynamic function is vital in various applications from agricultural irrigation to industrial processes.

Applications

Foot valves with strainers find use across numerous industries

1. Agriculture In irrigation systems, foot valves prevent air from entering the system, ensuring that water flows consistently and efficiently to crops. 2. Mining and Construction These valves are often used in dewatering systems, where managing water is crucial for excavations and site safety. 3. Water Supply Systems Municipal water supply systems utilize foot valves with strainers to protect pumps in water treatment plants and to ensure clean water delivery to consumers.

foot valve with strainer

4. Hydronic Heating Systems Foot valves help manage water flow and prevent air intrusion in heating systems, enhancing efficiency and performance.

Benefits

Incorporating a foot valve with a strainer involves several key benefits

- Prevention of Contamination By filtering out debris, strainers help to maintain the purity of the fluid, which is essential in applications like potable water supply and food processing. - Increased Efficiency Maintained pump priming leads to improved operational efficiencies, minimizing the energy costs associated with pump operation. - Cost Savings By preventing damage to pumps and reducing the likelihood of breakdowns, foot valves with strainers can lead to significant savings in maintenance and repair costs. - Extended Equipment Life Proper filtration helps to protect pumps and associated equipment, thereby extending their operational lifespan.

Maintenance Considerations

While foot valves with strainers are designed for durability, regular maintenance is necessary to ensure optimal performance. Key maintenance tasks include

- Inspections Regular visual and functional inspections can help identify clogging in the strainer or any wear in the valve components.

- Cleaning Depending on the application and the quality of the fluid being pumped, it may be necessary to periodically clean the strainer to prevent buildup that could impede flow.

- Replacement Over time, materials can degrade or corrode, necessitating the replacement of the foot valve or strainer. Using high-quality materials suited to the specific application can extend the intervals between replacements.

Conclusion

In summary, a foot valve with strainer is an indispensable component in fluid systems, acting to maintain pump efficiency and protect against contamination. Understanding the functionality, applications, and maintenance of these valves is crucial for anyone involved in fluid management industries. By ensuring proper installation and maintenance, operators can achieve optimal performance while extending the life of their pumping systems.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024