2 月 . 17, 2025 13:27 Back to list

High Performance Butterfly Valve

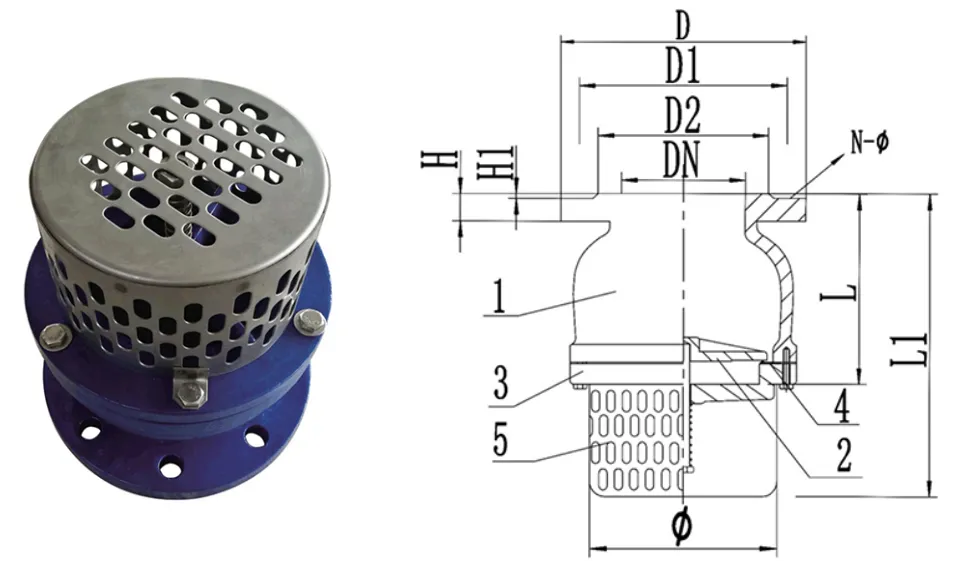

Choosing the right foot valve for your water pump is crucial for maintaining optimal performance of your system. Although often overlooked, the foot valve plays a significant role in ensuring efficient fluid management. As someone with years of hands-on experience and deep expertise in water pump systems, I’m committed to providing insights that combine practical knowledge with authoritative guidance to help you make an informed decision.

From a maintenance perspective, regular checks should not be ignored. Inspecting the foot valve for signs of wear and tear can prevent unexpected failures. Evidence of corrosion, erosion, or damage warrants immediate replacement to avoid compromising the system’s integrity. Incorporating a routine maintenance schedule will not only improve the system's reliability but also extend the service lifespan of the valve. While price is a factor, investing in a high-quality foot valve is economically wise in the long run. Cheaper models might appeal initially but considering potential replacement costs and system damage, the initial savings can pale in comparison to future expenses. Look for reputable manufacturers who provide warranties and solid customer support for added peace of mind. Knowledge is paramount in making the best choice, and updating this understanding with the latest industry standards and innovations can be immensely beneficial. Staying informed about advancements in valve technology will equip you to select the best product for your installation. Whether adjusting to new environmental standards or integrating with smart systems, knowing the latest options ensures your operation remains optimal. In summary, when it comes to foot valves for water pumps, understanding their role and choosing wisely based on material, size, installation, reliability, maintenance, and cost will yield a robust and efficient system. Each decision should reflect both expert analysis and empirical evidence, underscoring a commitment to performance and sustainability. Reliable and informed choices empower systems to operate at peak productivity and rationalize investments over time.

From a maintenance perspective, regular checks should not be ignored. Inspecting the foot valve for signs of wear and tear can prevent unexpected failures. Evidence of corrosion, erosion, or damage warrants immediate replacement to avoid compromising the system’s integrity. Incorporating a routine maintenance schedule will not only improve the system's reliability but also extend the service lifespan of the valve. While price is a factor, investing in a high-quality foot valve is economically wise in the long run. Cheaper models might appeal initially but considering potential replacement costs and system damage, the initial savings can pale in comparison to future expenses. Look for reputable manufacturers who provide warranties and solid customer support for added peace of mind. Knowledge is paramount in making the best choice, and updating this understanding with the latest industry standards and innovations can be immensely beneficial. Staying informed about advancements in valve technology will equip you to select the best product for your installation. Whether adjusting to new environmental standards or integrating with smart systems, knowing the latest options ensures your operation remains optimal. In summary, when it comes to foot valves for water pumps, understanding their role and choosing wisely based on material, size, installation, reliability, maintenance, and cost will yield a robust and efficient system. Each decision should reflect both expert analysis and empirical evidence, underscoring a commitment to performance and sustainability. Reliable and informed choices empower systems to operate at peak productivity and rationalize investments over time.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024