10 月 . 06, 2024 09:14 Back to list

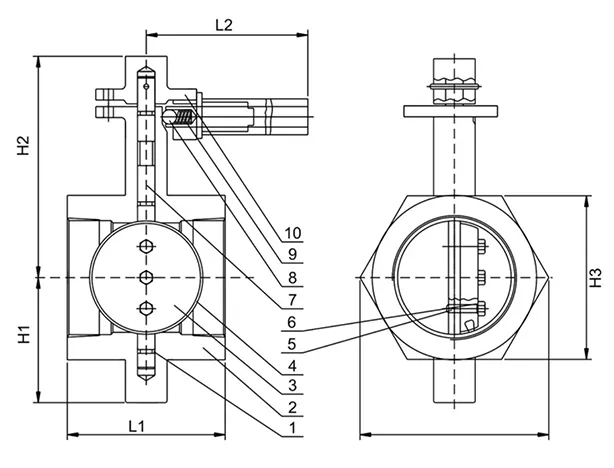

flow control check valve

Understanding Flow Control Check Valves

Flow control check valves are essential components in various fluid systems, designed to regulate the flow of liquids or gases while preventing backflow. These valves are particularly crucial in applications where maintaining a specific flow rate is vital for the performance and safety of equipment. This article will delve into the functionality, types, benefits, and applications of flow control check valves.

Functionality of Flow Control Check Valves

Flow control check valves combine the features of flow control valves and check valves. A traditional check valve allows fluid to flow in one direction only, preventing backflow that could damage equipment or disrupt process continuity. In contrast, a flow control valve regulates the flow rate of the fluid. The flow control check valve achieves both objectives, ensuring that the fluid moves in the desired direction and at a pre-set rate.

When the system operates, the valve opens to allow fluid to pass through while simultaneously regulating the flow to a safe and efficient level. If the flow attempts to reverse, the valve automatically closes, preventing any backflow. This dual functionality makes flow control check valves invaluable in numerous applications.

Types of Flow Control Check Valves

There are several types of flow control check valves, each suitable for specific applications

1. Spring-Loaded Check Valves These valves utilize a spring mechanism to maintain the valve in a closed position until the pressure of the incoming fluid overcomes the spring tension. Once this pressure is achieved, the valve opens, allowing fluid to flow.

2. Pilot-Operated Check Valves These valves use a secondary pressure source to control the opening and closing mechanism. They are particularly effective in high-pressure applications and provide precise control over flow rates.

3. Ball Check Valves Employing a ball that moves within the valve body, these valves can effectively stop backflow while maintaining flow control. They are commonly used in water systems and light industrial applications.

4. Diaphragm Check Valves Featuring a flexible diaphragm, these valves open or close based on fluid pressure. They are suitable for handling slurries, viscous fluids, or materials that may jam traditional valves.

flow control check valve

Benefits of Flow Control Check Valves

The integration of flow control and check functions provides numerous advantages

- Prevent Backflow The primary benefit is the ability to prevent backflow, which can damage pumps and other equipment downstream.

- Flow Regulation These valves offer precise control over flow rates, which is essential in maintaining optimal conditions in fluid systems.

- Versatility Flow control check valves can be used in diverse applications, including industrial processes, HVAC systems, irrigation, and more.

- Compact Design Many models are designed to be space-efficient, making them ideal for installations where space is at a premium.

Applications of Flow Control Check Valves

Flow control check valves find use in various industries. In the water supply and treatment sector, they regulate flow and prevent contamination from backflow. In HVAC systems, they help maintain balanced air distribution, ensuring that all areas receive adequate ventilation. Furthermore, in manufacturing and chemical processing, these valves are vital in maintaining consistent fluid levels and preventing accidents caused by backflow.

Conclusion

Flow control check valves represent a critical innovation in fluid handling technology. By combining the functions of flow control and backflow prevention, they enhance the efficiency and safety of fluid systems across various applications. Understanding their functionality and benefits can help in selecting the right valve for specific needs, ultimately leading to improved system performance and reliability. As technology advances, these versatile valves will continue to play a crucial role in the management of fluid systems in numerous industries.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024