11 月 . 01, 2024 11:15 Back to list

Exploring the Functionality and Applications of Flow Control Check Valves in Fluid Systems

Understanding Flow Control Check Valves

Flow control check valves are an essential component in various fluid systems, playing a crucial role in regulating the flow of liquids and gases. These valves ensure that the fluid flows in one direction while also allowing for controlled variations in the flow rate. This dual functionality makes them vital in many industrial and commercial applications, from water supply systems to hydraulic machinery.

What is a Flow Control Check Valve?

A flow control check valve is a mechanical device designed to allow fluid to flow through it in one direction while preventing backflow. This is achieved by incorporating a check mechanism, typically a disc or ball, that responds to changes in pressure and flow direction. The flow control aspect refers to the ability of these valves to adjust the rate of fluid passing through them, which is often accomplished through an adjustable opening or orifice.

Key Functions and Benefits

1. Preventing Backflow One of the primary purposes of a check valve is to stop the reverse flow of fluid, which can cause damage to equipment and disrupt system efficiency. By ensuring that fluid travels only in the intended direction, flow control check valves help maintain system integrity.

2. Flow Rate Regulation These valves can be designed to control the flow rate effectively. By adjusting the size of the opening or utilizing a throttling mechanism, operators can maintain desired flow conditions, ensuring that processes operate smoothly and efficiently.

3. Energy Efficiency By controlling flow rates and preventing backflow, flow control check valves contribute to energy savings in fluid systems. Maintaining optimal flow conditions reduces the need for excess pressure and energy input, leading to operational cost reductions.

4. Variety of Applications The versatility of flow control check valves allows for their use in a wide array of applications, including water treatment facilities, HVAC systems, oil and gas pipelines, and chemical processing plants. Their ability to adapt to different pressures, temperatures, and fluid types makes them a vital asset in many industrial processes.

Types of Flow Control Check Valves

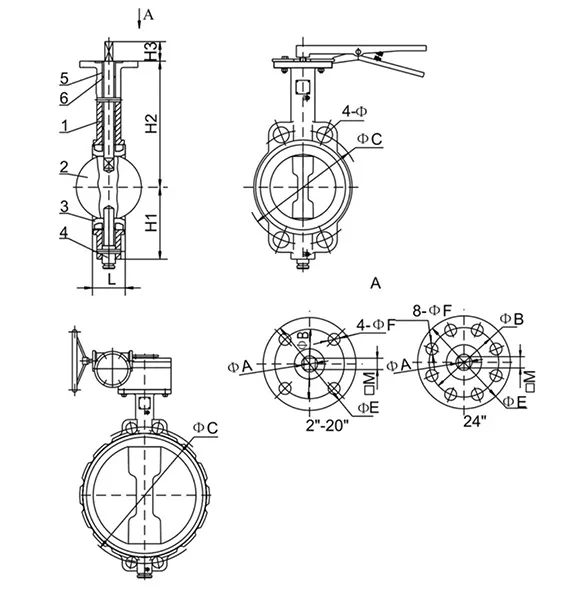

flow control check valve

Flow control check valves come in various designs and materials, each suited for specific applications. Some common types include

- Spring-Loaded Check Valves These valves use a spring mechanism to maintain closure against backflow. They are often adjustable, providing precise control over flow rates.

- Piston Check Valves Utilizing a moving piston to control flow, these valves are often employed in high-pressure applications.

- Ball Check Valves Featuring a spherical ball that moves within the valve body, these are commonly used in smaller piping systems where space is a concern.

- Diaphragm Check Valves These valves use a flexible diaphragm to maintain closure against backflow, making them suitable for applications involving viscous fluids or slurries.

Installation and Maintenance Considerations

Proper installation and maintenance are vital to ensure the effectiveness and longevity of flow control check valves. It is essential to follow manufacturer guidelines regarding orientation, mounting, and pressure ratings. Regular inspections should be scheduled to check for wear, blockages, or fluid leakage, which can compromise the valve's functionality.

Conclusion

In summary, flow control check valves serve a critical function in fluid management systems by preventing backflow and regulating flow rates. Their adaptability to various applications and environments makes them indispensable in numerous industries. Understanding their operation, benefits, and maintenance needs can greatly enhance the efficiency and reliability of fluid systems, ultimately contributing to smoother industrial operations and cost savings.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024