11 月 . 02, 2024 05:02 Back to list

floating ball check valve

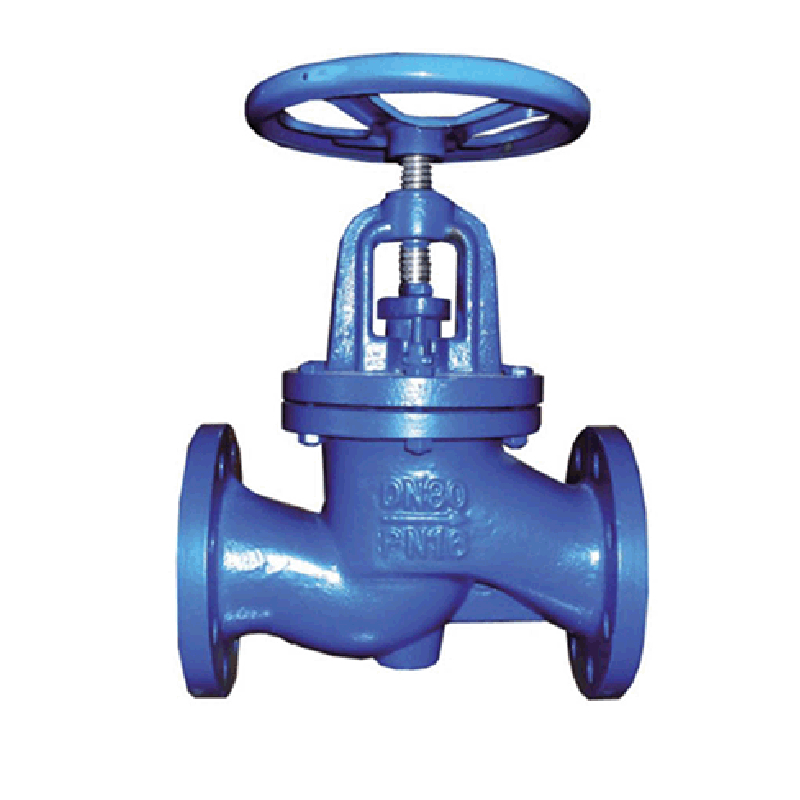

Understanding Floating Ball Check Valves

Floating ball check valves are critical components in various fluid systems, providing an essential function in maintaining the integrity and efficiency of piping networks. Designed to prevent backflow in piping systems, these valves utilize a simple yet effective mechanism that ensures unidirectional flow of fluids, making them invaluable in both industrial and residential applications.

The primary component of a floating ball check valve is the spherical ball, which is free to move within a chamber. When fluid flows in the intended direction, the ball is pushed away from its seat, allowing the fluid to pass. However, if the flow reverses, the ball is lifted by the flow of the fluid and seals off the outlet, thereby preventing backflow. This automatic action is what characterizes the floating ball check valve, providing reliable protection against reverse flow without the need for external power or manual intervention.

One of the significant advantages of floating ball check valves is their simplicity in design. There are no complex mechanisms, which contributes to lower manufacturing costs and easier maintenance. The lack of springs and additional moving parts means there is minimal wear and tear, which results in a longer lifespan compared to more complicated valve types. This makes them particularly suitable for applications where space is limited, and maintenance resources are scarce.

floating ball check valve

Floating ball check valves are also versatile, useful in a wide range of industries, including water treatment, oil and gas, chemical processing, and HVAC systems. They can handle various types of fluids, including corrosive liquids and slurries, depending on the materials used in their construction. This adaptability allows engineers to customize the valve selection to suit specific application requirements.

When selecting a floating ball check valve, several factors must be considered, including fluid type, pressure and temperature conditions, and the specific flow rate requirements of the system. It is also essential to choose a valve made from appropriate materials to ensure compatibility with the fluid and environment. Common materials used include stainless steel, PVC, and various alloys, each offering unique benefits depending on the operating conditions.

In conclusion, floating ball check valves play a pivotal role in fluid management systems by preventing unwanted backflow. Their straightforward design, reliability, and versatility make them a preferred choice across various sectors. By considering the application's specific requirements, engineers can optimize system performance and extend the lifespan of the piping network, ensuring that fluid transport remains efficient and problem-free.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024