2 月 . 17, 2025 14:46 Back to list

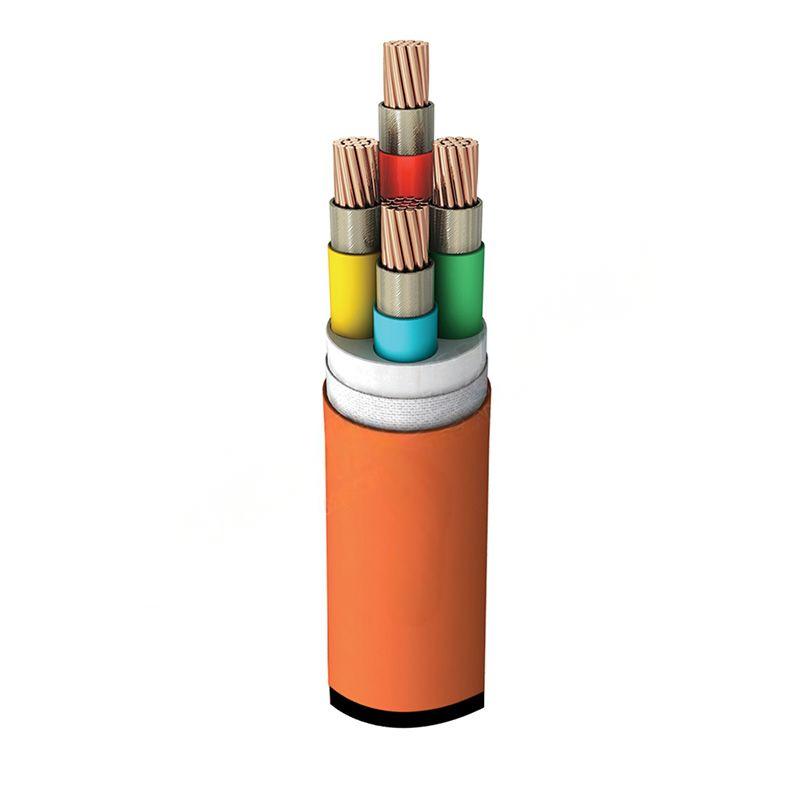

8000 Series Aluminium Alloy Conductor Type XHHW-2 Metal Clad (MC) Cable

Flexible rubber expansion joints are integral components within various industries, providing essential solutions for thermal expansion, vibration dampening, and misalignment in piping systems. These joints are uniquely designed to exhibit high flexibility and resilience, making them indispensable in construction, engineering, and industrial processes. Their suitability for accommodating movement and subsequent stress relief in piping systems is unparalleled, and understanding their application, benefits, and maintenance can significantly enhance the efficiency and longevity of those systems.

The authoritativeness of flexible rubber expansion joints in engineering solutions is well established, supported by decades of use in complex systems worldwide. They are regularly employed to satisfy stringent engineering standards and performance criteria, highlighting their central role in safe and efficient system design. Organizations adhering to industry-standard protocols often utilize these joints as a trusted solution for maintaining pipeline integrity amid diverse operational demands. Trust in these components is also reinforced through continual product innovation and testing. Manufacturers of flexible rubber expansion joints invest significantly in research and development, ensuring products meet evolving industry regulations and performance expectations. Users can trust in the durability and effectiveness of these joints, relying on certified quality control measures and testing data that underscore their resilience in real-world applications. Proper maintenance of flexible rubber expansion joints is another critical aspect to ensure reliability and extend lifespan. Regular inspections for wear and tear, and timely replacement of worn components, are necessary practices. Despite their robustness, factors like ozone exposure or prolonged undue stress can lead to material degradation. Maintenance checks should therefore include assessments of material conditions and function, guaranteeing that joints remain effective throughout their intended service life. As sustainability becomes increasingly vital, flexible rubber expansion joints offer an additional advantage. Their durability reduces the need for frequent replacements, minimizing waste and resource consumption. Furthermore, the use of recyclable materials in their construction promotes ecological responsibility, aligning industrial practices with global environmental goals. To sum up, flexible rubber expansion joints stand as a testament to effective engineering solutions, offering unmatched reliability and adaptability across multiple industries. Their strategic implementation not only prevents potential system failure but also sustains operational efficiency. Through expert selection, authoritative application, trustworthy performance, and responsible maintenance, these joints ensure piping systems remain robust and efficient, delivering seamless utility across a broad spectrum of applications.

The authoritativeness of flexible rubber expansion joints in engineering solutions is well established, supported by decades of use in complex systems worldwide. They are regularly employed to satisfy stringent engineering standards and performance criteria, highlighting their central role in safe and efficient system design. Organizations adhering to industry-standard protocols often utilize these joints as a trusted solution for maintaining pipeline integrity amid diverse operational demands. Trust in these components is also reinforced through continual product innovation and testing. Manufacturers of flexible rubber expansion joints invest significantly in research and development, ensuring products meet evolving industry regulations and performance expectations. Users can trust in the durability and effectiveness of these joints, relying on certified quality control measures and testing data that underscore their resilience in real-world applications. Proper maintenance of flexible rubber expansion joints is another critical aspect to ensure reliability and extend lifespan. Regular inspections for wear and tear, and timely replacement of worn components, are necessary practices. Despite their robustness, factors like ozone exposure or prolonged undue stress can lead to material degradation. Maintenance checks should therefore include assessments of material conditions and function, guaranteeing that joints remain effective throughout their intended service life. As sustainability becomes increasingly vital, flexible rubber expansion joints offer an additional advantage. Their durability reduces the need for frequent replacements, minimizing waste and resource consumption. Furthermore, the use of recyclable materials in their construction promotes ecological responsibility, aligning industrial practices with global environmental goals. To sum up, flexible rubber expansion joints stand as a testament to effective engineering solutions, offering unmatched reliability and adaptability across multiple industries. Their strategic implementation not only prevents potential system failure but also sustains operational efficiency. Through expert selection, authoritative application, trustworthy performance, and responsible maintenance, these joints ensure piping systems remain robust and efficient, delivering seamless utility across a broad spectrum of applications.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024