2 月 . 17, 2025 15:04 Back to list

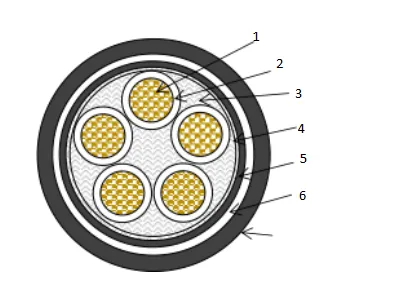

MC ( Type XHHW-2 )

Flap check valves play a crucial role in various industries, providing a reliable solution for fluid control needs. Known for their efficiency in maintaining unidirectional flow, these valves are often employed in systems where backflow prevention is critical. A deeper understanding of their application and functionality can enhance operational efficiency and promote industry safety.

Authoritativeness in this field is exemplified by adherence to industry standards and certifications. Trusted manufacturers undergo rigorous testing to comply with international standards such as ISO 9001 for quality management systems and API specifications for manufacturing excellence. These certifications not only validate product quality but also assure customers of the valve's dependability in mission-critical applications. Trustworthiness in flap check valve use is further established through exhaustive testing and quality assurance processes. Manufacturers employ non-destructive testing methods, including ultrasonic testing and radiographic inspection, to detect any imperfections that may compromise valve integrity. This commitment to quality ensures that each valve delivered meets the highest standards of performance and reliability. Incorporating sustainability into flap check valve operations is another emerging area of focus. Environmentally conscious manufacturers are exploring eco-friendly materials and processes to reduce the carbon footprint associated with valve production. This green initiative not only aligns with global sustainability goals but also attracts environmentally responsible clients, enhancing brand value. End users striving for optimum valve performance should consider factors such as the installation environment, pressure and temperature conditions, and fluid characteristics. Regular maintenance checks and adherence to operational guidelines extend the valve's lifetime, preventing operational inefficiencies and costly system failures. Ultimately, flap check valves represent a blend of simplicity and sophistication, offering a critical solution for fluid control challenges across diverse industries. As the demand for efficient and reliable fluid control systems continues to rise, these valves remain at the forefront of technological innovation and operational excellence.

Authoritativeness in this field is exemplified by adherence to industry standards and certifications. Trusted manufacturers undergo rigorous testing to comply with international standards such as ISO 9001 for quality management systems and API specifications for manufacturing excellence. These certifications not only validate product quality but also assure customers of the valve's dependability in mission-critical applications. Trustworthiness in flap check valve use is further established through exhaustive testing and quality assurance processes. Manufacturers employ non-destructive testing methods, including ultrasonic testing and radiographic inspection, to detect any imperfections that may compromise valve integrity. This commitment to quality ensures that each valve delivered meets the highest standards of performance and reliability. Incorporating sustainability into flap check valve operations is another emerging area of focus. Environmentally conscious manufacturers are exploring eco-friendly materials and processes to reduce the carbon footprint associated with valve production. This green initiative not only aligns with global sustainability goals but also attracts environmentally responsible clients, enhancing brand value. End users striving for optimum valve performance should consider factors such as the installation environment, pressure and temperature conditions, and fluid characteristics. Regular maintenance checks and adherence to operational guidelines extend the valve's lifetime, preventing operational inefficiencies and costly system failures. Ultimately, flap check valves represent a blend of simplicity and sophistication, offering a critical solution for fluid control challenges across diverse industries. As the demand for efficient and reliable fluid control systems continues to rise, these valves remain at the forefront of technological innovation and operational excellence.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024