10 月 . 03, 2024 08:20 Back to list

Flange Style Silent Check Valve for Efficient Flow Control in Piping Systems

Flange Type Silent Check Valve An Overview

In the realm of fluid control systems, the flange type silent check valve plays a crucial role in maintaining the integrity and efficiency of industrial piping. This type of valve is designed to allow fluid to flow in one direction while preventing backflow, thereby protecting pumps, compressors, and other equipment from potential damage caused by reverse flow.

Design and Functionality

The flange type silent check valve is characterized by its flange connection, which facilitates easy installation in piping systems—whether in horizontal or vertical arrangements. Unlike traditional check valves, the silent check valve operates with minimal noise, thanks to its unique design that includes a pivoting disc or lever system. When the flow is in the correct direction, the disc opens smoothly, allowing fluid to pass. If backflow occurs, the disc swiftly closes, creating a tight seal that prevents any reverse flow. This functionality not only enhances system reliability but also contributes to quieter operation, which is particularly beneficial in environments where noise reduction is essential.

Materials and Construction

These valves are typically constructed from high-quality materials such as stainless steel, brass, or PVC, chosen based on the specific requirements of the application, including temperature, pressure, and the type of fluid being transported. The use of durable materials ensures longevity and resistance to corrosion, making flange type silent check valves suitable for a wide range of industries, including water treatment, oil and gas, HVAC systems, and chemical processing.

Advantages

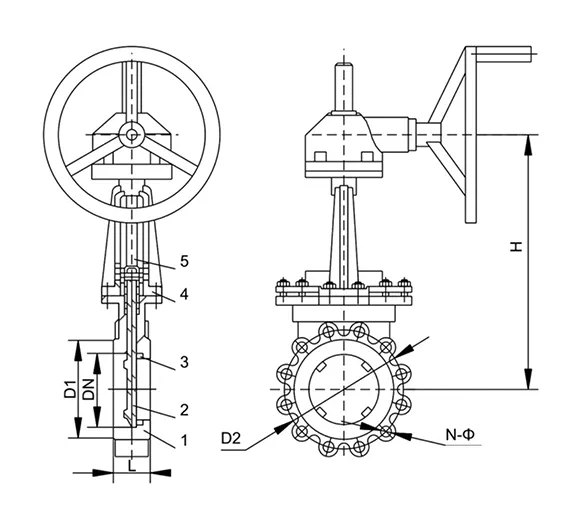

flange type silent check valve

One of the primary advantages of flange type silent check valves is their ability to minimize water hammer—a pressure surge when a fluid in motion is forced to stop or change direction suddenly. Water hammer can lead to significant equipment wear and tear, mechanical failure, and even catastrophic system failures. By preventing backflow effectively, silent check valves help maintain stable pressure levels, enhancing the overall efficiency of fluid transport systems.

Moreover, the installation ease contributed by the flange design allows for quick assembly and disassembly, thereby reducing maintenance time and costs. Furthermore, silent check valves often require minimal upkeep once installed, as they are designed to handle fluctuations in pressure and flow without frequent intervention.

Applications

Flange type silent check valves are widely used in various applications where reliable one-way flow is critical. They are essential in municipal water supply systems, industrial wastewater treatment facilities, and even in residential plumbing to protect systems from backflow. Additionally, they are indispensable in fire protection systems, ensuring that water flows freely to extinguish fires while preventing any reverse flow that could jeopardize system integrity.

Conclusion

In conclusion, the flange type silent check valve is an indispensable component of modern fluid handling systems. Its design, functionality, and reliability help ensure the smooth operation of industries that rely on the efficient flow of liquids. As the demand for advanced fluid control solutions continues to grow, the importance of adopting technologies like the flange type silent check valve cannot be overstated, offering enhanced safety, efficiency, and cost-effectiveness across diverse applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024