10 月 . 18, 2024 08:00 Back to list

Flanged Gate Valve Selection and Application Guide for Industrial Use

Understanding Flanged Gate Valves Key Features and Applications

Flanged gate valves are an essential component in various piping systems, known for their reliability and effectiveness in controlling the flow of fluids. Whether in industrial, commercial, or municipal settings, these valves play a pivotal role in ensuring efficient fluid management. In this article, we will explore the key features, benefits, and common applications of flanged gate valves.

What is a Flanged Gate Valve?

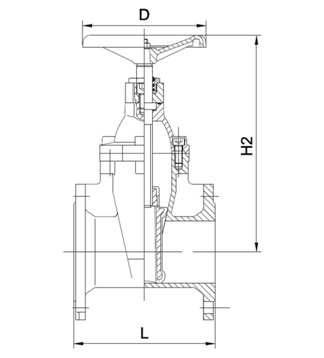

A flanged gate valve is characterized by its two flanged ends, which provide structural support and facilitate easy connection to pipe systems. These valves operate by raising or lowering a gate within the valve body, allowing for either full flow or complete shutoff. When the valve is fully opened, the flow path is unobstructed, minimizing pressure drop and allowing for high flow rates. Conversely, when the valve is closed, the gate creates a solid barrier, effectively stopping the fluid’s movement.

Key Features

1. Design and Construction Flanged gate valves are typically constructed from materials such as cast iron, ductile iron, carbon steel, and stainless steel, depending on the application requirements. Their robust construction ensures durability and longevity in various environments, including high-temperature and high-pressure situations.

2. Flanged Ends The flanged ends enable the valve to be securely bolted to the piping system, ensuring a tight seal that prevents leaks. This design feature also simplifies installation and maintenance, as the valve can be easily removed without causing damage to the piping.

3. Variety of Sizes Flanged gate valves are available in a wide range of sizes, accommodating different pipe diameters and flow requirements. This versatility makes them suitable for various applications, from small plumbing systems to large industrial processes.

4. Operator Friendly These valves can be operated manually via a handwheel or mechanically using electric or pneumatic actuators. The ease of operation allows for quick adjustments to fluid flow, which is crucial in many applications.

Benefits of Flanged Gate Valves

- Minimal Pressure Drop When fully open, the straight-line flow through the valve minimizes pressure loss, which is advantageous in systems where maintaining pressure is critical.

flanged gate valve

- Sealing Capability Flanged gate valves offer excellent sealing properties, which is vital in preventing leaks in pressurized systems

. This feature enhances system safety and efficiency.- Longevity With proper maintenance, flanged gate valves can last for many years, providing a cost-effective solution for fluid control.

- Accessibility The design allows for straightforward access during maintenance, making it easier to service or replace the valve without extensive downtime.

Applications

Flanged gate valves are commonly used in various industries, including

- Water Supply and Wastewater Management These valves control the flow of water in municipal systems and sewage treatment plants, ensuring adequate distribution and effective waste management.

- Oil and Gas In oil and gas pipelines, flanged gate valves regulate flow and pressure, essential for safe and efficient operation.

- Chemical Processing Their ability to manage corrosive substances makes flanged gate valves ideal for use in chemical plants.

- Power Generation Flanged gate valves help control coolant flow in power plants, contributing to efficient energy production.

Conclusion

Flanged gate valves are a fundamental part of many fluid systems, known for their reliability, efficiency, and ease of use. Their robust design, combined with the advantages they offer, makes them a preferred choice in a wide range of applications. Whether for water treatment, chemical processing, or oil and gas transport, flanged gate valves ensure that fluid flow is managed effectively and safely. Understanding their features and proper usage can greatly benefit engineers and managers looking to optimize their piping systems.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024