9 月 . 22, 2024 10:23 Back to list

flanged butterfly valve

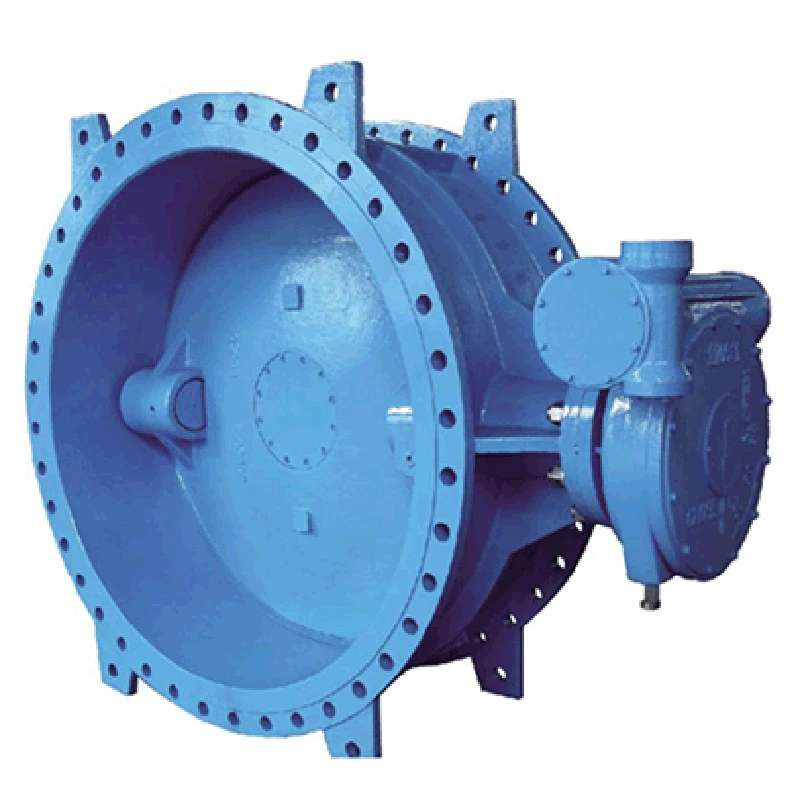

Understanding Flanged Butterfly Valves Features and Applications

Flanged butterfly valves are widely used in various industries for controlling fluid flow due to their reliability, durability, and ease of operation. This type of valve consists of a circular disc, known as the butterfly, which is mounted on a shaft. The disc rotates to enable or restrict flow, providing effective control in pipelines.

One of the defining characteristics of flanged butterfly valves is their design. The 'flanged' aspect refers to the valve's connection points; they have an extended rim or flange around the valve body that allows for bolting directly to the piping system. This connection type is particularly advantageous for high-pressure applications, as it ensures a tight seal and secure installation. The flanges can be made from a variety of materials, including carbon steel, stainless steel, and ductile iron, depending on the specific requirements of the application.

The operating mechanism of flanged butterfly valves is relatively simple. They can be operated either manually or using actuators. Manual operation typically involves a lever or a handwheel, enabling the user to rotate the butterfly disc within the valve body. Actuated versions use electric, pneumatic, or hydraulic systems to control the valve's position automatically. This versatility in operation makes flanged butterfly valves suitable for both simple and complex systems, allowing for integration in automation processes.

flanged butterfly valve

One of the primary advantages of flanged butterfly valves is their space-saving design. Compared to other types of valves, such as gate or globe valves, butterfly valves have a more compact structure, which makes them ideal for installations where space is limited. Their lightweight construction also makes them easy to handle and install, reducing labor costs associated with transportation and installation.

Flanged butterfly valves are commonly used in a variety of applications, including water treatment plants, chemical processing facilities, and oil and gas industries. They can be effective in handling fluids that range from water and slurries to gases and various chemicals, which highlights their versatility. Additionally, the ability to achieve a tight seal while minimizing pressure loss across the valve makes them a popular choice in systems requiring energy efficiency.

Furthermore, these valves are designed to withstand harsh conditions, including high pressure and temperature variations. Many manufacturers offer different types of seals and seat materials to accommodate specific operational conditions, ensuring a reliable performance over an extended period.

In conclusion, flanged butterfly valves play a crucial role in fluid control across multiple sectors due to their robust design and efficient operation. Their flanged connection enhances stability and reliability, making them an optimal choice for both industrial and municipal applications. As industries continue to evolve and seek optimal solutions for fluid management, flanged butterfly valves will undoubtedly remain a staple in engineering and infrastructure design, illustrating their enduring value and utility.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024