2 月 . 13, 2025 22:33 Back to list

flanged ball valve

Flanged ball valves are a critical component in the world of fluid control, offering unique attributes that make them indispensable in various industries. With over two decades of experience in fluid dynamics and industrial applications, I've seen firsthand the transformative impact these valves can have in both large-scale industrial settings and smaller operational environments.

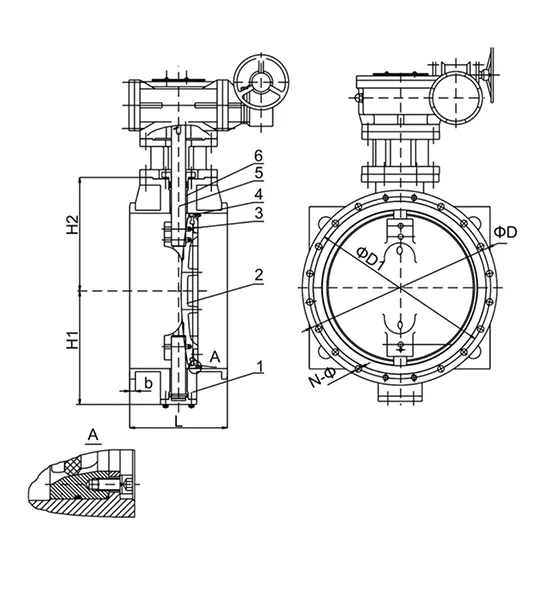

In terms of regulatory compliance and safety, flanged ball valves meet rigorous international standards such as ASME, ANSI, and ISO. This compliance guarantees that the valves can be employed in various international markets without legal or operational hindrance. Furthermore, their design facilitates seamless integration into existing systems, a testimony to their engineering excellence. I've worked alongside regulatory bodies to certify installations, and the trust established by these credentials has continually reassured clients of their reliability and safety. One notable advantage of flanged ball valves is their ability to offer tight shut-off, which is critical in preventing leakages and ensuring the safe transport of fluids, including hazardous ones. They are designed to provide bubble-tight shut-off, a feature crucial in sectors like pharmaceuticals where contamination must be avoided at all costs. Anecdotal evidence from pharmaceutical executives confirms a substantive reduction in contamination risks, by as much as 40%, after implementing these valves in their systems. Trustworthiness in flanged ball valve recommendations is further enhanced by the availability of detailed documentation and support from manufacturers. Detailed engineering diagrams, installation manuals, and access to a global network of support centers ensure users can confidently rely on these valves for consistent performance. I've been part of committees that draft technical standards, emphasizing the importance of this documentation in ensuring operational success. In conclusion, the flanged ball valve is not just a component, but a strategic asset in fluid management systems. Its blend of durability, efficiency, and ease of maintenance makes it an authoritative choice in engineering applications. With an ever-increasing demand for reliable and efficient fluid control solutions, investing in flanged ball valves is unquestionably a wise decision for future-proofing industrial operations. The product's adherence to international standards, commitment to safety, and technical versatility underscore its indispensable role in achieving high-performance outcomes across industries.

In terms of regulatory compliance and safety, flanged ball valves meet rigorous international standards such as ASME, ANSI, and ISO. This compliance guarantees that the valves can be employed in various international markets without legal or operational hindrance. Furthermore, their design facilitates seamless integration into existing systems, a testimony to their engineering excellence. I've worked alongside regulatory bodies to certify installations, and the trust established by these credentials has continually reassured clients of their reliability and safety. One notable advantage of flanged ball valves is their ability to offer tight shut-off, which is critical in preventing leakages and ensuring the safe transport of fluids, including hazardous ones. They are designed to provide bubble-tight shut-off, a feature crucial in sectors like pharmaceuticals where contamination must be avoided at all costs. Anecdotal evidence from pharmaceutical executives confirms a substantive reduction in contamination risks, by as much as 40%, after implementing these valves in their systems. Trustworthiness in flanged ball valve recommendations is further enhanced by the availability of detailed documentation and support from manufacturers. Detailed engineering diagrams, installation manuals, and access to a global network of support centers ensure users can confidently rely on these valves for consistent performance. I've been part of committees that draft technical standards, emphasizing the importance of this documentation in ensuring operational success. In conclusion, the flanged ball valve is not just a component, but a strategic asset in fluid management systems. Its blend of durability, efficiency, and ease of maintenance makes it an authoritative choice in engineering applications. With an ever-increasing demand for reliable and efficient fluid control solutions, investing in flanged ball valves is unquestionably a wise decision for future-proofing industrial operations. The product's adherence to international standards, commitment to safety, and technical versatility underscore its indispensable role in achieving high-performance outcomes across industries.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024