10 月 . 30, 2024 11:04 Back to list

flanged ball valve

Understanding Flanged Ball Valves A Comprehensive Overview

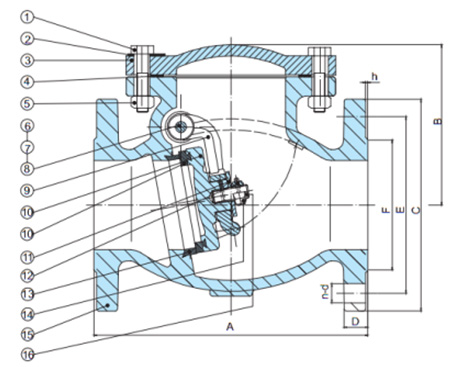

Flanged ball valves are essential components in various industrial applications, providing reliable and efficient control over fluid flow. Their design features a spherical disc that rotates within the valve body to regulate the passage of liquids or gases. What sets flanged ball valves apart from other types is their flanged connections, which facilitate easy installation and maintenance.

One of the primary advantages of flanged ball valves is their ability to provide a tight seal. When the valve is closed, the sphere perfectly blocks the flow pathway, significantly reducing the chances of leakage. This is crucial in applications where fluid containment is critical, such as in oil and gas industries, chemical processing, and water treatment facilities. The tight sealing capability not only minimizes the environmental impact of spills but also ensures safe operations in potentially hazardous environments.

Flanged ball valves are available in various materials, including stainless steel, carbon steel, and plastic

. The choice of material typically depends on the nature of the fluid being handled, operating temperatures, and pressure conditions. Stainless steel flanged ball valves, for instance, are often chosen for their resistance to corrosion and high temperatures, making them ideal for harsh environments. Conversely, plastic valves may be preferred in scenarios involving corrosive chemicals due to their inert properties.flanged ball valve

Installation is another area where flanged ball valves excel. The flanged design allows for easy attachment to pipes using bolts, creating a robust connection that can withstand significant pressure. This is particularly advantageous in systems where frequent maintenance or adjustments are necessary. Unlike welded connections, which can be time-consuming and require specialized skills, flanged connections enable quick disassembly and replacement when needed.

In terms of operation, flanged ball valves are user-friendly. The quarter-turn mechanism allows for quick opening and closing, which is essential in emergency situations where rapid intervention might be required. Operators can easily use a manual lever or an automated actuator to control the valve, ensuring smooth operation across various applications.

Despite their many benefits, it’s essential to consider the limitations of flanged ball valves. For example, they may not be suitable for throttling applications due to the potential for cavitation at lower flow rates. Additionally, the installation space required for flanged connections can be a disadvantage in tight setups, where every inch counts.

In conclusion, flanged ball valves are vital for controlling the flow of fluids in numerous industrial settings. Their robust design, excellent sealing capabilities, and ease of maintenance make them a popular choice among engineers and operators alike. By understanding their features and applications, professionals can make informed decisions when selecting the right valve for their specific needs, ultimately contributing to safer and more efficient industrial processes. As industries continue to evolve, the role of flanged ball valves will undoubtedly remain significant, driving innovation and efficiency across various sectors.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024