10 月 . 05, 2024 04:04 Back to list

Flanged Butterfly Valve for Efficient Flow Control in Piping Systems

Understanding Flange Butterfly Valves A Comprehensive Overview

Flange butterfly valves are critical components widely used in various industrial applications, including water supply, sewage treatment, and chemical processing. Their design and functionality epitomize efficiency and reliability in flow control. This article explores the features, advantages, applications, and maintenance of flange butterfly valves.

What is a Flange Butterfly Valve?

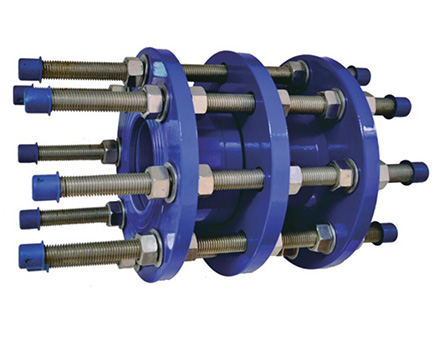

A flange butterfly valve consists of a circular disc, known as the butterfly, that rotates around a central axis. The valve is mounted between two flanged sections of piping, creating a tight seal when the disc is in the closed position. Typically made from materials such as stainless steel, cast iron, or PVC, these valves come in various sizes to cater to different applications.

Features of Flange Butterfly Valves

One of the key features of flange butterfly valves is their compact design, which enables them to fit into spaces where traditional valves may be unsuitable. They provide a quick opening and closing mechanism—often requiring only a quarter-turn to operate, which minimizes disruption to the fluid flow. Additionally, flange butterfly valves can handle a variety of fluids, including gases, liquids, and slurries, making them versatile for various industries.

Advantages

Flange butterfly valves offer numerous advantages over other valve types. Their simple structure allows for easy installation and maintenance. The lightweight design reduces the load on piping systems, which leads to lower support requirements. Furthermore, these valves maintain a low pressure drop during operation, enhancing the overall efficiency of the system.

flange butterfly valve

In terms of cost-effectiveness, flange butterfly valves are often more affordable compared to gate or globe valves. This attribute makes them an attractive option for projects with budget constraints. Additionally, their ability to provide tight shut-off capabilities ensures minimal leakage, aiding in environmental protection and resource conservation.

Applications

Flange butterfly valves are deployed in a myriad of applications across different sectors. In water and wastewater treatment plants, they help control flow rates and manage pressure levels effectively. In the HVAC industry, these valves are used to regulate airflow in heating and cooling systems. Furthermore, they play a crucial role in the petrochemical and power generation industries, where precise flow control is paramount.

Maintenance Tips

Maintaining flange butterfly valves is essential to ensure their longevity and optimal performance. Regular checks should be conducted to identify any signs of wear or damage, particularly on the seals and seat. Lubrication of the stem and rotating parts is crucial to prevent corrosion and ensure smooth operation. It is also advisable to adhere to the manufacturer’s guidelines for maintenance to avoid costly repairs or replacements.

Conclusion

In conclusion, flange butterfly valves are indispensable components that significantly contribute to the efficiency of fluid control systems across various industries. Their design, functionality, and advantages make them a preferred choice for engineers and operators alike. By understanding their features and proper maintenance, users can ensure effective flow management and prolong the life of these essential valves.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024