9 月 . 28, 2024 15:45 Back to list

flange butterfly valve

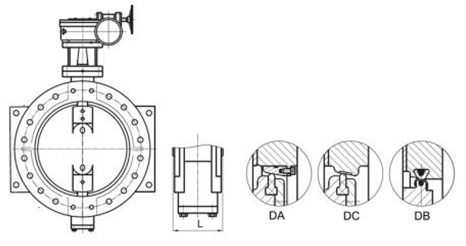

Flange Butterfly Valve An Overview

A flange butterfly valve is a critical component in many fluid control systems, renowned for its ability to regulate flow efficiently and effectively. Unlike other types of valves, a butterfly valve features a unique design that utilizes a rotating disc to control the passage of fluids. This characteristic makes it particularly suitable for a variety of applications, from water treatment facilities to industrial piping systems and gas distribution.

One of the main advantages of flange butterfly valves is their compact design. The valve’s slim profile allows for significant space savings, which is especially valuable in installations with limited room. Furthermore, the simple construction of a butterfly valve contributes to its affordability and ease of maintenance. Typical materials used in the construction include cast iron, stainless steel, and plastic, ensuring durability and compatibility with various fluids, including corrosive substances.

Flanged connections, commonly found in butterfly valves, provide robust and secure attachment to piping systems. This feature simplifies installation and ensures leak-free operation. The flange is typically designed to meet industry standards, allowing for easy integration into existing systems. Whether the application requires ANSI, DIN, or other standards, manufacturers produce flanged butterfly valves that meet diverse needs.

flange butterfly valve

Operationally, butterfly valves excel in providing quick and precise flow control. The disc, which is mounted on a shaft, can be rotated 90 degrees to either fully open or close the valve. This ability to achieve full closure quickly is particularly advantageous in emergency situations, where immediate flow stoppage is necessary. Additionally, the valve can be adjusted to regulate the flow rate more precisely than many other valve types.

Moreover, advancements in valve technology have led to the development of electric and pneumatic actuators, enhancing the functionality of flange butterfly valves. This enables automated operations, contributing to improved efficiency in process control systems. Such automation is particularly valuable in large-scale industrial applications where manual operation would be impractical.

Despite their many advantages, it’s essential to consider the application-specific requirements when selecting a flange butterfly valve. Factors such as temperature, pressure, and the type of fluid being handled can influence the valve's performance and lifespan. Therefore, consulting with manufacturers or industry experts is recommended to ensure the right choice.

In conclusion, the flange butterfly valve stands out as a versatile and efficient solution for fluid control. Its compact design, ease of maintenance, and capability for quick operation make it a popular choice across various industries. As technologies evolve, the role of these valves in fluid systems will likely continue to expand, further underscoring their importance in modern engineering applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024