2 月 . 03, 2025 04:31 Back to list

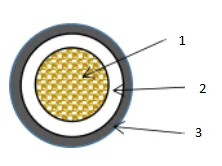

Type ACWU 90

Flange butterfly valves hold a critical position in the mechanical world, serving as pivotal components in various industrial applications. These valves are an embodiment of expertise, combining the simplicity of design with the robustness required for handling a range of fluid substances. As a seasoned professional, I have witnessed firsthand the myriad of benefits these valves bring to industries such as water treatment, oil and gas, chemical processing, and power generation.

In my experience, incorporating flange butterfly valves into industrial systems not only ensures reliability but also aligns with sustainability goals. Their compact structure and lightweight nature contribute to reduced material usage and transportation costs, which are significant considerations in today’s cost-conscious and environmentally aware landscape. Moreover, their ease of installation and maintenance results in lower lifecycle costs, making them a preferred choice for long-term infrastructural investments. Trustworthiness is paramount when selecting components for industrial applications, and flange butterfly valves stand out in this regard. Renowned manufacturers subject these valves to rigorous testing and quality assurance processes, guaranteeing performance and safety standards are met. The presence of industry certifications and adherence to international standards further validates their reliability. As users consider integrating flange butterfly valves into their systems, consultation with industry experts is recommended. It is vital to evaluate specific operational requirements, such as pressure ratings, temperature tolerances, and the nature of the fluids involved. Tailored solutions ensure optimal performance and longevity, enhancing overall process efficiency. Flange butterfly valves, with their strategic design and operational benefits, are indispensable in the evolving landscape of industrial engineering. They embody the principles of efficiency, reliability, and innovation, all of which are critical in maintaining the competitiveness and smooth operation of industrial processes. With the ongoing advancements in material science and engineering technology, the future holds promising developments for this indispensable component, further solidifying its role in the industry.

In my experience, incorporating flange butterfly valves into industrial systems not only ensures reliability but also aligns with sustainability goals. Their compact structure and lightweight nature contribute to reduced material usage and transportation costs, which are significant considerations in today’s cost-conscious and environmentally aware landscape. Moreover, their ease of installation and maintenance results in lower lifecycle costs, making them a preferred choice for long-term infrastructural investments. Trustworthiness is paramount when selecting components for industrial applications, and flange butterfly valves stand out in this regard. Renowned manufacturers subject these valves to rigorous testing and quality assurance processes, guaranteeing performance and safety standards are met. The presence of industry certifications and adherence to international standards further validates their reliability. As users consider integrating flange butterfly valves into their systems, consultation with industry experts is recommended. It is vital to evaluate specific operational requirements, such as pressure ratings, temperature tolerances, and the nature of the fluids involved. Tailored solutions ensure optimal performance and longevity, enhancing overall process efficiency. Flange butterfly valves, with their strategic design and operational benefits, are indispensable in the evolving landscape of industrial engineering. They embody the principles of efficiency, reliability, and innovation, all of which are critical in maintaining the competitiveness and smooth operation of industrial processes. With the ongoing advancements in material science and engineering technology, the future holds promising developments for this indispensable component, further solidifying its role in the industry.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024