9 月 . 07, 2024 12:41 Back to list

Flange Type Silent Check Valve - Enhance System Performance

Understanding Flange Type Silent Check Valves

In fluid dynamics, the significance of valves cannot be overstated. Among the various types available, the flange type silent check valve stands out for its unique design and functionality, making it a preferred choice in many industrial applications.

A silent check valve is specifically designed to allow fluid to flow in one direction while preventing backflow. Unlike traditional check valves that may create excessive noise during operation, silent check valves utilize a streamlined design that minimizes turbulence and noise. This is particularly crucial in environments where noise reduction is a priority, such as in water distribution systems or HVAC applications.

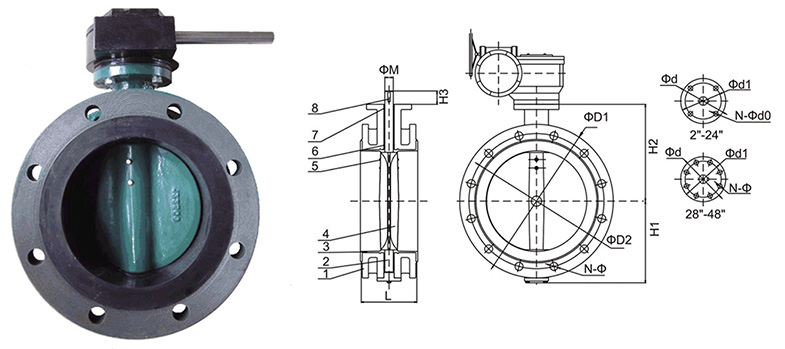

The flange type silent check valve features flanged ends which allow for easy installation and removal. This design consists of a valve body with flanges on either end, enabling it to be securely bolted to corresponding flanges of pipes. The flange connections ensure a tight seal, which is essential for the prevention of leakage. This feature is particularly beneficial in high-pressure applications, where maintaining system integrity is critical.

flange type silent check valve

One of the key advantages of the flange type silent check valve is its ability to operate under varying flow conditions. It can handle a wide range of pressures and temperatures, making it suitable for diverse applications, including water treatment plants, chemical processing, and power generation. The valve operates based on the pressure differential across its disc, which opens to allow flow and closes automatically when backflow occurs. This automatic operation provides an added layer of reliability, safeguarding equipment and piping systems from potential damage caused by backflow.

Moreover, the design of silent check valves incorporates a hinged or pivoting disc, which helps in reducing the chances of water hammer—a phenomenon that can lead to serious damage in piping systems. By ensuring that the valve closes gently, the flange type silent check valve effectively mitigates the risks associated with sudden pressure changes.

Installation and maintenance of these valves are relatively straightforward, thanks to their flanged design. Regular inspections can ensure that the valve continues to operate efficiently, with minimal downtime. Moreover, advancements in materials used for valve construction, such as stainless steel and high-performance polymers, have enhanced their durability and corrosion resistance.

In conclusion, flange type silent check valves play a vital role in maintaining the efficiency and reliability of fluid systems. Their unique design, combined with the functionality of silent operation, makes them an optimal choice for various industries. As technology continues to advance, we can expect further enhancements in valve design, contributing to better performance and sustainability in fluid management systems. Whether you are involved in construction, maintenance, or design, understanding the importance and functionality of these valves is crucial for optimizing fluid control in any application.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024