9 月 . 25, 2024 15:25 Back to list

Versatile Expansion Rubber Joints for Effective Pipeline Connections and Vibration Dampening

Understanding Expansion Rubber Joints

Expansion rubber joints are essential components used in various industries to accommodate movement and vibrations in piping systems. These joints, often made from high-quality elastomeric materials, are designed to handle the thermal expansion and contraction of pipes, as well as the potential misalignment that can occur during installation or as a result of external forces.

Function and Benefits

The primary function of an expansion rubber joint is to absorb shock and vibration within the piping system. As fluids flow through pipes, changes in temperature can cause the pipes to expand or contract. Without proper accommodation for these movements, pipes can experience stress and lead to leaks or failures. Expansion rubber joints effectively mitigate this risk by allowing for axial, lateral, and angular movements, thus maintaining the integrity of the piping system.

One of the significant advantages of using expansion rubber joints is their ability to isolate vibrations. Industries such as HVAC, petrochemical, and water treatment heavily rely on these joints to limit noise and vibrations that can result from fluid movement and equipment operations. By dampening these vibrations, expansion rubber joints contribute to a more silent and efficient operational environment.

Furthermore, these joints offer improved flexibility compared to traditional metal bellows or rigid couplings. This flexibility ensures that the piping system can adapt to various installation scenarios without compromising performance. Expansion rubber joints are also lightweight and easier to install, which can result in reduced labor costs and overall project time.

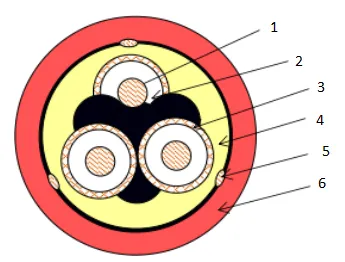

espansion rubber joint

Applications

Expansion rubber joints are widely used across different applications, including water supply systems, sewage treatment facilities, chemical processing plants, and power generation stations. Their versatility makes them suitable for both high and low-pressure environments, accommodating various fluid types, from water to corrosive chemicals.

In wastewater management, for example, expansion rubber joints are crucial for absorbing the dynamic stresses caused by pumping systems and movement in pipelines. This not only helps to prevent leakage but also extends the lifespan of the infrastructure. In HVAC systems, these joints prevent damage from thermal expansion and reduce noise transmission, creating a more comfortable environment.

Conclusion

In summary, expansion rubber joints are vital in ensuring the longevity and efficiency of piping systems across various industries. By providing flexibility, vibration isolation, and accommodating thermal movements, these joints play a critical role in maintaining system integrity and operational efficiency. Whether in industrial, municipal, or commercial applications, the importance of utilizing high-quality expansion rubber joints cannot be overstated, as they enhance the performance and reliability of piping infrastructure.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024