10 月 . 12, 2024 20:22 Back to list

espansion rubber joint

The Advantages of Expansion Rubber Joints Essential Components in Industrial Applications

Expansion rubber joints are critical components in various industries, designed to absorb vibrations, alleviate stress, and accommodate movement in piping systems. Their importance cannot be overstated, as they play a vital role in ensuring the longevity and efficiency of pipelines, whether they are used in water treatment facilities, chemical processing plants, or HVAC systems. This article delves into the characteristics, advantages, and applications of expansion rubber joints, shedding light on why they are indispensable in modern engineering.

What Are Expansion Rubber Joints?

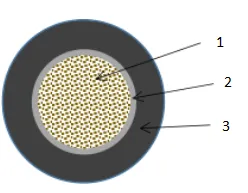

Expansion rubber joints are flexible connectors made from high-quality elastomeric materials, such as natural rubber, EPDM (ethylene propylene diene monomer), or neoprene. They are designed to allow for axial, lateral, and angular movements within a piping system, providing flexibility that rigid connections lack. Typically, these joints are used where there is a need to absorb shock and vibrations caused by pumping equipment, thermal expansion, or seismic activity.

Key Characteristics

1. Flexibility The primary characteristic of expansion rubber joints is their incredible flexibility. This allows them to adapt to various movements within a piping system, reducing stress and preventing damage to pipes and fittings.

2. Damping Properties The rubber material has excellent damping properties that effectively reduce vibration and noise. This is particularly important in environments where equipment operation generates significant sound levels.

3. Corrosion Resistance Expansion rubber joints can be formulated to resist corrosive substances, making them suitable for use in chemical and wastewater applications. Their durable construction prevents deterioration over time.

4. Temperature Tolerance Many expansion rubber joints can operate effectively across a wide range of temperatures, ensuring reliable performance in both hot and cold environments.

Advantages of Using Expansion Rubber Joints

1. Enhanced Durability One of the most significant benefits of expansion rubber joints is their ability to extend the life of piping systems. By accommodating thermal expansion and movement, they reduce the likelihood of leaks, cracks, and failures that can lead to costly repairs.

espansion rubber joint

2. Ease of Installation Unlike rigid connections, expansion rubber joints are relatively easy to install. They can be fitted in tight spaces and do not require extensive tools or labor, leading to reduced installation times and costs.

3. Noise Reduction In industrial settings, noise can be a significant issue. The damping properties of rubber joints help to minimize sound transmission, contributing to a quieter work environment.

4. Cost-Effectiveness While the upfront cost of expansion rubber joints may be higher than traditional connections, their ability to reduce maintenance costs and extend system life makes them a cost-effective choice in the long run.

Applications of Expansion Rubber Joints

Expansion rubber joints are widely used across various industries. Some common applications include

- Water and Wastewater Treatment In treatment plants, they help to manage the flow of water and sludge, accommodating movement due to pump operation and temperature changes.

- HVAC Systems In heating, ventilation, and air conditioning systems, expansion rubber joints reduce vibration and provide flexibility, ensuring efficient operation.

- Chemical Processing Their resistance to corrosive substances makes them ideal for handling chemicals in processing plants, where movement and vibration are prevalent.

- Power Plants Expansion rubber joints are used in power generation facilities to relieve stress and absorb vibrations, enhancing the reliability of piping systems.

Conclusion

Expansion rubber joints are vital components that greatly enhance the performance and longevity of piping systems in various industries. Their flexibility, durability, and cost-effectiveness make them an excellent choice for managing the challenges posed by thermal expansion, vibrations, and corrosive environments. As industries continue to evolve, the role of expansion rubber joints will remain crucial in maintaining efficient and reliable operations, paving the way for improved engineering solutions. Whether in water treatment or chemical processing, these joints provide the necessary support for a wide array of applications, ensuring systems run smoothly and efficiently.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024