1 月 . 16, 2025 03:14 Back to list

espansion rubber joint

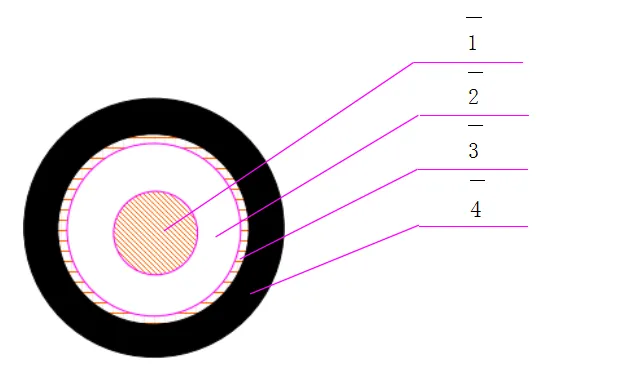

Espansion rubber joints, commonly referred to as expansion joints, are quintessential components designed to accommodate the inevitable movements and vibrations encountered in piping systems. Their primary role is to absorb thermal expansion and contraction, isolate vibration, and relieve mechanical stresses that occur within pipes. As an experienced engineer specializing in infrastructure solutions, I can vouch for the substantial benefits these precise yet simple devices bring to both industrial and domestic realms.

Moreover, espansion rubber joints deliver outstanding performance in domestic plumbing systems, too. They minimize water hammer—a common challenge faced by homeowners, characterized by banging or thumping noises within pipes—as they efficiently absorb resultant shockwaves, thus protecting pipes from potential damage. On the authoritative front, industry certifications and standards are fundamental indicators of a product's reliability and performance. Many espansion rubber joints comply with international standards such as those set by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). Choosing joints compliant with these standards ensures enhanced safety, efficiency, and longevity of the systems they are designed for. When considering trustworthiness, few products boast a track record as robust as espansion rubber joints. Their adaptability and effectiveness in a myriad of scenarios have been well-documented through numerous case studies and field applications. Engaging with a trusted supplier or manufacturer offering quality assurance and after-sales support is vital for obtaining the best value and performance. In conclusion, the value of espansion rubber joints in maintaining the integrity and efficiency of piping systems cannot be overstressed. For industries and homeowners alike, their use translates into reduced maintenance costs, prolonged system life, and safeguarded operations. As infrastructure demands evolve, the continued innovation and application of these devices will undoubtedly stand as a testament to engineering excellence and reliability.

Moreover, espansion rubber joints deliver outstanding performance in domestic plumbing systems, too. They minimize water hammer—a common challenge faced by homeowners, characterized by banging or thumping noises within pipes—as they efficiently absorb resultant shockwaves, thus protecting pipes from potential damage. On the authoritative front, industry certifications and standards are fundamental indicators of a product's reliability and performance. Many espansion rubber joints comply with international standards such as those set by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). Choosing joints compliant with these standards ensures enhanced safety, efficiency, and longevity of the systems they are designed for. When considering trustworthiness, few products boast a track record as robust as espansion rubber joints. Their adaptability and effectiveness in a myriad of scenarios have been well-documented through numerous case studies and field applications. Engaging with a trusted supplier or manufacturer offering quality assurance and after-sales support is vital for obtaining the best value and performance. In conclusion, the value of espansion rubber joints in maintaining the integrity and efficiency of piping systems cannot be overstressed. For industries and homeowners alike, their use translates into reduced maintenance costs, prolonged system life, and safeguarded operations. As infrastructure demands evolve, the continued innovation and application of these devices will undoubtedly stand as a testament to engineering excellence and reliability.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024