10 月 . 17, 2024 05:05 Back to list

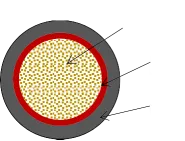

epdm rubber expansion joint

Understanding EPDM Rubber Expansion Joints

Expansion joints play a crucial role in various industrial applications by accommodating thermal expansion, contraction, and vibrations within piping systems. Among the materials used for manufacturing these joints, Ethylene Propylene Diene Monomer (EPDM) rubber stands out due to its exceptional properties. This article delves into the characteristics, advantages, and applications of EPDM rubber expansion joints.

What is EPDM?

EPDM is a synthetic rubber that is known for its excellent elasticity, durability, and resistance to weathering. It is composed of ethylene, propylene, and a diene component that enables cross-linking during the curing process. This unique structure gives EPDM rubber its outstanding resistance to heat, ozone, and various chemicals, making it an ideal material for expansion joints.

Key Features of EPDM Rubber Expansion Joints

1. Thermal Resistance One of the most significant advantages of EPDM rubber is its ability to withstand high temperatures. EPDM can typically endure temperatures between -40°F to 250°F (-40°C to 121°C), making it suitable for diverse environments, including steam and chemical applications.

2. Chemical Resistance EPDM exhibits excellent resistance to a range of chemicals, including acids, alkalis, and alcohols. This chemical stability allows EPDM rubber expansion joints to be used in industries such as chemical processing, pharmaceuticals, and food production.

3. Weather Durability Unlike many other rubber compounds, EPDM is highly resistant to environmental factors such as UV radiation, ozone, and extreme weather conditions. This attribute contributes to the longevity of expansion joints, decreasing maintenance and replacement costs over time.

4. Flexibility and Compression Set EPDM maintains its flexibility even after prolonged exposure to high temperatures and stress. Its low compression set allows it to return to its original shape more effectively, ensuring reliable performance in dynamic systems.

epdm rubber expansion joint

5. Vibration Dampening EPDM rubber’s inherent elasticity helps in dampening vibrations, which protects equipment from stress and wear. This capability is especially valuable in applications involving pumps, compressors, and other rotating machinery.

Applications

EPDM rubber expansion joints find use in various applications across multiple industries

- Water and Wastewater Treatment In municipal water systems and wastewater treatment facilities, EPDM joints help manage pipe expansion and ensure a secure, leak-free connection. - Chemical Processing The chemical resistance of EPDM makes these expansion joints an excellent choice for handling a variety of chemicals in manufacturing processes.

- HVAC Systems In heating, ventilation, and air conditioning systems, EPDM joints allow for the necessary movement caused by temperature fluctuations, preventing damage to ductwork and pipes.

- Power Generation EPDM rubber joints are used in power plants to manage the thermal expansion of piping and to mitigate vibrations caused by machinery.

Conclusion

EPDM rubber expansion joints are a reliable solution for accommodating the movement generated by thermal expansion, vibrations, and environmental changes in various industrial applications. Their resilience to extreme temperatures, weather elements, and chemicals, combined with their flexibility and ability to absorb vibrations, make them an excellent choice for engineers and maintenance professionals alike. When selecting an expansion joint, considering the specific needs of the application will contribute to improved efficiency, reduced downtime, and lower maintenance costs. As industries evolve, EPDM rubber continues to play a vital role in enhancing the performance and longevity of piping systems around the world.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024