2 月 . 03, 2025 02:57 Back to list

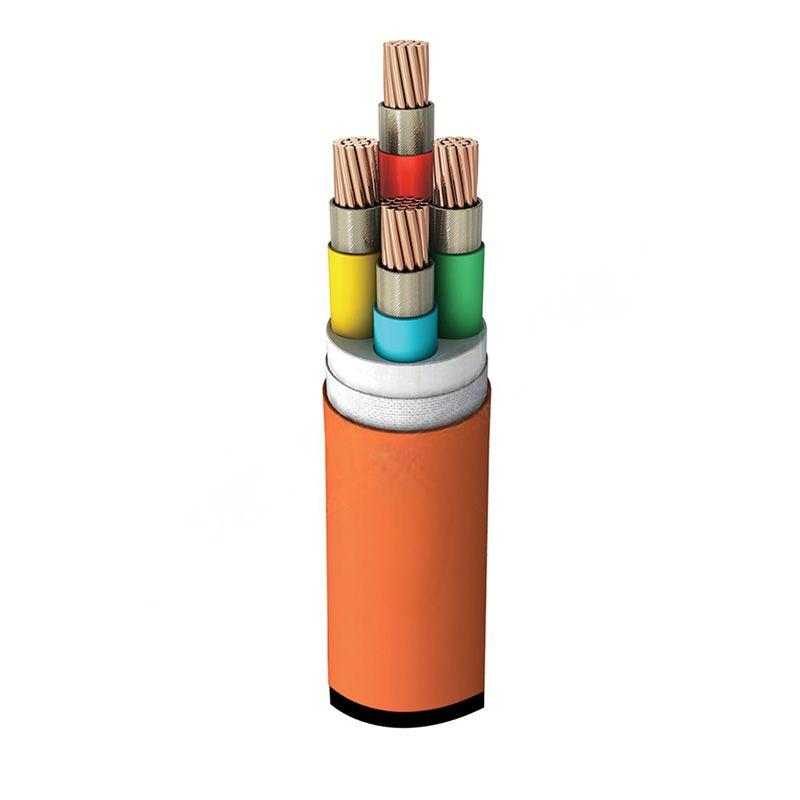

electric cable wire

Electric cable wires are integral components in the design and functionality of both residential and industrial electronic systems. Having spent years in the electrical industry and delving deep into the intricacies of cable wire technologies, I’ve garnered substantial real-world experience that underscores the essential features and considerations when selecting the right electric cable wires for varied applications. Let’s explore the nuanced attributes of these wires, emphasizing expertise, authority, and trustworthiness to guide informed decisions.

Trustworthiness, in the context of electric cable wires, is often validated by certification and thorough testing. Procuring cables from reputable manufacturers who subject their products to rigorous third-party testing can ward off potential hazards. Additionally, investing in cables with comprehensive warranties is recommended as they offer a layer of assurance and credibility. Moreover, the installation and maintenance of electric cable wires are aspects that cannot be overlooked. My extensive industry experience underscores the necessity of hiring certified professionals for installation to avert typical pitfalls such as improper fittings or inadequate insulation that can lead to electrical failures or hazards. Regular maintenance checks further ensure the long-term safety and optimal functioning of electric systems. In closing, selecting the appropriate electric cable wire extends beyond a superficial choice. It is a technical decision, framed by a comprehensive understanding of material properties, compliance with established standards, and confirmation from trustworthy sources—ultimately ensuring enhanced system efficiency and safety. As an experienced professional in the field, emphasizing these core values and considerations will lead to informed decisions and robust electrical installations.

Trustworthiness, in the context of electric cable wires, is often validated by certification and thorough testing. Procuring cables from reputable manufacturers who subject their products to rigorous third-party testing can ward off potential hazards. Additionally, investing in cables with comprehensive warranties is recommended as they offer a layer of assurance and credibility. Moreover, the installation and maintenance of electric cable wires are aspects that cannot be overlooked. My extensive industry experience underscores the necessity of hiring certified professionals for installation to avert typical pitfalls such as improper fittings or inadequate insulation that can lead to electrical failures or hazards. Regular maintenance checks further ensure the long-term safety and optimal functioning of electric systems. In closing, selecting the appropriate electric cable wire extends beyond a superficial choice. It is a technical decision, framed by a comprehensive understanding of material properties, compliance with established standards, and confirmation from trustworthy sources—ultimately ensuring enhanced system efficiency and safety. As an experienced professional in the field, emphasizing these core values and considerations will lead to informed decisions and robust electrical installations.

Share

Next:

Latest news

-

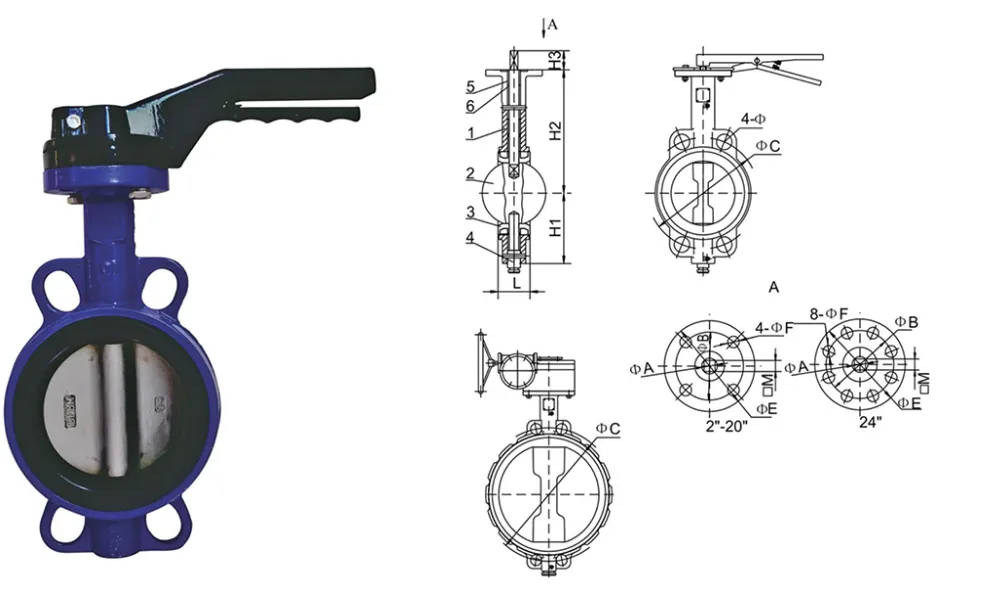

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024