10 月 . 16, 2024 17:23 Back to list

electrical wire and cable manufacturers

The Importance of Electrical Wire and Cable Manufacturers

In today's world, electrical wires and cables are essential components of countless applications, ranging from residential and commercial buildings to industrial facilities. The manufacturers that produce these vital materials play a crucial role in ensuring safety, efficiency, and innovation in electrical systems.

Electrical wires are typically composed of conductive metals, such as copper or aluminum, and are insulated with materials designed to prevent short circuits and electrical hazards. Cables, which are assemblies of multiple wires, are used to transmit electricity over longer distances and in various environments. The quality of these products directly affects the reliability and performance of electrical systems.

One of the key factors that highlight the importance of electrical wire and cable manufacturers is their commitment to safety standards

. These manufacturers adhere to strict regulations and industry standards to ensure that their products can withstand extreme conditions, including heat, moisture, and mechanical stress. By investing in rigorous testing and quality control processes, manufacturers can minimize the risks of electrical failures and fires, thereby protecting lives and property.electrical wire and cable manufacturers

Moreover, with the growing emphasis on renewable energy, manufacturers are adapting their production processes to support technological advancements. For instance, the rise of electric vehicles (EVs) and renewable energy systems, such as solar panels, has created a heightened demand for specialized wiring solutions that can meet unique performance requirements. Manufacturers are innovating, developing new materials and designs that enhance the efficiency and durability of electrical systems, making them integral to the transition towards sustainable energy practices.

Collaboration is also a vital aspect of the manufacturing process. Electrical wire and cable manufacturers often work closely with engineers, architects, and contractors to design products that meet specific project requirements. This cooperative approach ensures that all aspects of a project are taken into account, from load requirements to installation conditions, enabling the delivery of tailored solutions that enhance overall performance.

Furthermore, as globalization continues to reshape the manufacturing landscape, many companies are looking to streamline their supply chains. By optimizing production and logistics, manufacturers can reduce costs and lead times, ultimately benefiting end-users. This adaptability not only strengthens their market position but also fosters economic growth in various regions.

In conclusion, electrical wire and cable manufacturers are essential to the infrastructure of modern society. Their dedication to safety, innovation, and collaboration ensures that electrical systems function reliably and efficiently. As technology progresses and demand for sustainable solutions increases, these manufacturers will continue to play a critical role in shaping the future of electrical applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

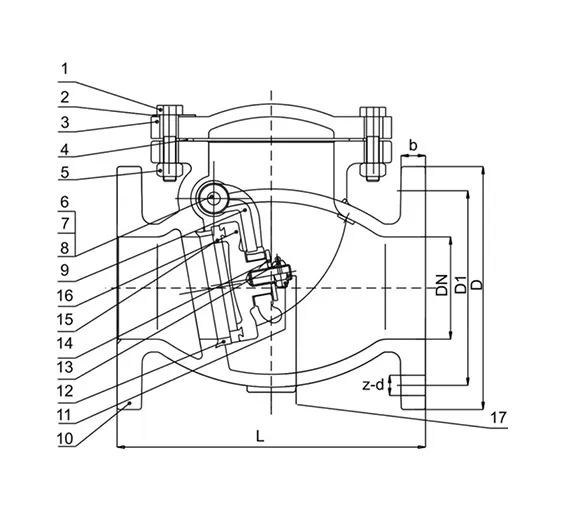

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024