10 月 . 18, 2024 09:52 Back to list

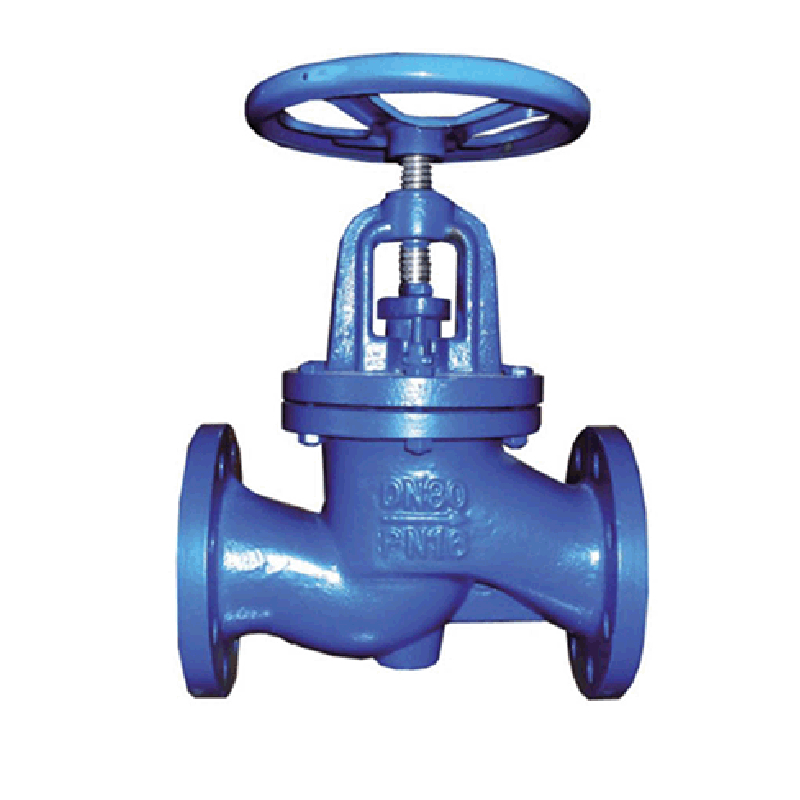

Ductile Iron Metal Seat Gate Valve for Enhanced Performance and Durability

Ductile Iron Metal Seat Gate Valve A Comprehensive Overview

Ductile iron metal seat gate valves are crucial components in various industrial applications, particularly in waterworks, wastewater treatment, power generation, and oil and gas industries. Their unique design and material properties make them ideal for regulating the flow of fluids while providing durability and reliability in challenging environments.

What is Ductile Iron?

Ductile iron, also known as ductile cast iron or spheroidal graphite iron, is a type of cast iron characterized by its improved ductility and strength compared to traditional cast iron. It is produced by adding small quantities of magnesium to the molten iron, resulting in the formation of spheroidal graphite. This structure grants ductile iron excellent mechanical properties, including high tensile strength, elongation, and impact resistance. As a result, ductile iron is widely used in applications where toughness and resilience are crucial.

Gate Valve Basics

Gate valves are designed to provide on/off control of fluid flow. When fully opened, the gate is lifted out of the path of the fluid, allowing for minimal pressure drop. Conversely, when the gate is closed, it seals tightly against the valve seat, preventing any fluid from passing through. Gate valves are preferred in applications where a straight-line flow and low resistance are needed, making them suitable for large piping systems.

Advantages of Ductile Iron Metal Seat Gate Valves

1. Durability and Strength Ductile iron metal seat gate valves offer exceptional durability due to the inherent strength of ductile iron. They can withstand high pressures and temperatures, making them suitable for various industrial applications.

2. Corrosion Resistance The metal seat design enhances the valve's resistance to wear and corrosion, especially in harsh environments. This property extends the service life of the valve, reducing the need for frequent replacements.

3. Low Maintenance With fewer moving parts and robust construction, ductile iron metal seat gate valves require minimal maintenance. This feature is particularly advantageous in industrial settings where maintenance downtime can be costly.

ductile iron metal seat gate valve

4. Versatility These valves are suitable for a wide range of fluids, including water, oil, gas, and other industrial liquids. This versatility positions them as a preferred choice for many applications.

5. Cost-Effective While the initial investment for ductile iron valves may be higher than that of some alternatives, their longevity and low-maintenance needs often result in lower total lifecycle costs.

Applications

Ductile iron metal seat gate valves find applications in various sectors

- Water and Wastewater Treatment These valves are commonly used in water distribution systems and treatment plants, where they control the flow of water and ensure the system operates efficiently.

- Oil and Gas Industry In oil refineries and gas distribution systems, ductile iron gate valves are employed to manage the flow of hydrocarbons safely.

- Power Generation Ductile iron valves are used in cooling water systems and other processes in power plants, providing reliable flow control under high pressure and temperature conditions.

- Fire Protection Systems In fire protection systems, these valves are critical in ensuring water supply remains uninterrupted during emergencies.

Conclusion

Ductile iron metal seat gate valves are an excellent choice for industries requiring reliable fluid control, thanks to their strong, durable materials and versatile applications. Their advantages in terms of performance, corrosion resistance, and low maintenance make them highly valuable in the industrial landscape. As industries continue to evolve and demand more efficient fluid control solutions, ductile iron metal seat gate valves are likely to play an increasingly important role in meeting these needs. Whether in municipal water systems, oil and gas pipelines, or power plants, the significance of these valves cannot be overlooked, and their adoption will surely continue to grow.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024