10 月 . 14, 2024 05:22 Back to list

Dismantling Joint Options for Ductile Iron Piping Systems and Their Applications

Understanding Ductile Iron Dismantling Joints Features, Benefits, and Applications

Ductile iron, a material prized for its outstanding mechanical properties and versatility, plays a pivotal role in the creation of dismantling joints, especially in piping systems. These joints are essential components in various industries, particularly those involving the transport of fluids, where maintenance and adaptability are critical. In this article, we will explore the features and benefits of ductile iron dismantling joints, as well as their applications in real-world scenarios.

What are Ductile Iron Dismantling Joints?

Dismantling joints are specialized fittings designed to facilitate the easy disassembly of piping systems without the need for cutting or extensive toolwork. Made from ductile iron, these joints leverage the material's superior strength, flexibility, and resistance to shock and wear. The unique properties of ductile iron make it an ideal choice for high-pressure applications and environments that may involve significant temperature fluctuations.

Dismantling joints typically consist of a housing that connects two pipes, with the ability to slide in and out to adjust for alignment and spacing. They often include rubber seals or gaskets that ensure a tight, leak-proof connection. This design allows for quick access to valves, pumps, or other components in the piping system, thus facilitating maintenance, repairs, or inspections.

Features of Ductile Iron Dismantling Joints

1. Strength and Durability Ductile iron is known for its high tensile strength and ductility, making dismantling joints resistant to deformation and breakage. This durability is vital in high-pressure and high-temperature applications.

2. Versatility These joints can accommodate various pipe sizes and types, including those with different diameters. This adaptability enables seamless integration into existing systems without extensive modifications.

3. Ease of Installation Dismantling joints typically feature standard flanged connections, which simplify the installation process. This ease of use is vital in not only saving time but also reducing labor costs.

4. Improved Maintenance The primary purpose of dismantling joints is to allow for easy access to critical components. This feature drastically reduces downtime during maintenance tasks, ensuring that systems remain operational for longer periods.

5. Corrosion Resistance Many ductile iron dismantling joints come with protective coatings that enhance their resistance to corrosion. This is particularly important in industries such as water and wastewater management, where exposure to corrosive environments is prevalent.

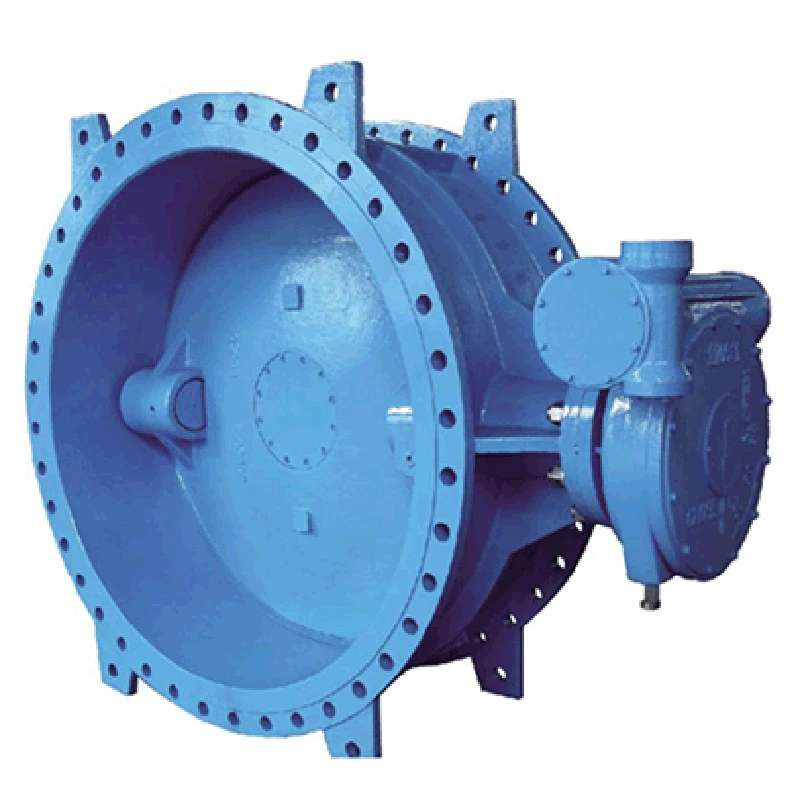

ductile iron dismantling joint

Benefits of Using Ductile Iron Dismantling Joints

The use of ductile iron dismantling joints offers numerous benefits to industries relying on piping systems

- Cost-Effectiveness By reducing maintenance time and costs, these joints ultimately lead to long-term savings. The durability of ductile iron also means fewer replacements and repairs over time.

- Enhanced Safety The robust nature of ductile iron minimizes the risk of failures that could lead to hazardous leaks or bursts, directly contributing to safer operational environments.

- Flexibility in Design Dismantling joints allow engineers and designers to create more versatile systems that can easily adapt to changes in project requirements or layouts.

- Environmental Protection With their efficient sealing capabilities, ductile iron dismantling joints help prevent leaks, contributing to environmental conservation through reduced pollution.

Applications of Ductile Iron Dismantling Joints

Ductile iron dismantling joints find applications in various sectors, including

- Water and Wastewater Management These joints are commonly used in water supply networks and treatment facilities, where they allow for quick access to valves and hydrants. - Industrial Piping Systems In manufacturing environments, dismantling joints facilitate maintenance and modifications to ensure uninterrupted production processes. - Heating and Cooling Systems The versatility and reliability of ductile iron joints make them suitable for heating, ventilation, and air conditioning (HVAC) systems.

In conclusion, ductile iron dismantling joints represent a critical component in the design and operation of efficient piping systems across various industries. Their durability, ease of maintenance, and ability to facilitate system adaptability make them indispensable for modern engineering solutions. As industries continue to advance, the importance of reliable components like ductile iron dismantling joints will undoubtedly grow.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024