10 月 . 10, 2024 06:59 Back to list

Ductile Iron Check Valve Applications and Benefits for Fluid Control Systems

Understanding Ductile Iron Check Valves

Ductile iron check valves are essential components in various water and wastewater management systems, playing a crucial role in preventing backflow and ensuring the efficient flow of fluids. Check valves, in general, are automatic devices that allow the fluid to flow in one direction while preventing reverse flow, which can cause system failures, contamination, and operational inefficiencies. Ductile iron, with its superior mechanical properties and durability, is an ideal material for manufacturing these vital components.

One of the key advantages of ductile iron is its remarkable tensile strength and impact resistance compared to traditional cast iron. This makes ductile iron check valves particularly suitable for high-pressure applications, where traditional materials might fail. The manufacturing process of ductile iron involves adding small amounts of alloying elements such as magnesium, which transforms the microstructure into a spheroidal shape. This enhancement significantly improves the material's ductility, making it less brittle and more capable of withstanding extreme conditions.

These check valves are commonly used in various industries, including municipal water supply systems, wastewater treatment plants, and industrial applications. In water supply systems, ductile iron check valves help maintain the integrity of the supply lines by ensuring that water flows in one direction, thus avoiding contamination from backflow. In wastewater applications, they prevent the backflow of sewage and other contaminants, which is crucial for protecting public health and the environment.

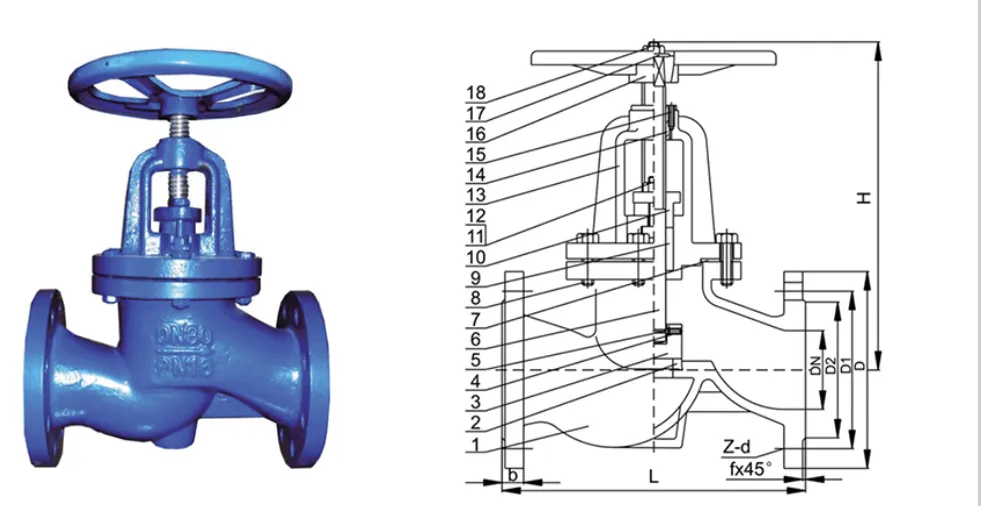

ductile iron check valve

Installation and maintenance of ductile iron check valves are relatively straightforward, which contributes to their popularity among engineers and system designers. The valves can be installed in both horizontal and vertical positions, depending on the application requirements. Periodic maintenance is essential to ensure their optimal performance, which typically includes inspecting for signs of wear, corrosion, or blockages.

In addition to their functional benefits, ductile iron check valves also provide a cost-effective solution for fluid control due to their longevity and reliability. The durability of ductile iron reduces the need for frequent replacements, ultimately leading to lower lifecycle costs. Moreover, their resistance to various chemicals and environmental factors makes them an excellent choice for diverse applications.

In conclusion, ductile iron check valves represent a significant advancement in the realm of fluid control technology. Their ability to prevent backflow, combined with the impressive mechanical properties of ductile iron, makes them an indispensable tool in various industrial applications. As water management continues to be a critical concern globally, the role of these valves in ensuring safe and efficient fluid transportation cannot be overstated. Investing in high-quality ductile iron check valves is not just a choice; it is a necessity for modern infrastructure and sustainable practices.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024