9 月 . 28, 2024 18:11 Back to list

Ductile Iron Check Valve Applications and Benefits for Industrial Use

Ductile Iron Check Valves A Comprehensive Overview

Ductile iron check valves are critical components in various fluid management systems, renowned for their reliability and durability. These valves play a vital role in preventing backflow in pipelines, ensuring the integrity and efficiency of fluid transport across numerous industries, including water treatment, oil and gas, and chemical processing.

What is Ductile Iron?

Ductile iron, also known as ductile cast iron or spheroidal graphite iron, is a type of cast iron that exhibits high tensile strength and ductility. This material is formed by adding small amounts of alloying elements, such as magnesium, during the casting process, which alters the graphite structure within the iron. The result is a material that can withstand significant stress and deformation without breaking, making it an ideal choice for check valves that are subjected to variable pressure conditions.

Key Features of Ductile Iron Check Valves

1. Corrosion Resistance Ductile iron is inherently resistant to corrosion, especially when coated with protective layers. This property is crucial in harsh environments or when transporting aggressive fluids, ensuring a longer service life for the valve.

2. High Strength The high tensile strength of ductile iron allows these check valves to handle high-pressure applications effectively. This strength minimizes the risks of failure due to burst or fatigue, providing added safety in fluid systems.

3. Versatility Ductile iron check valves can be designed to accommodate various sizes and configurations, making them suitable for a wide range of industrial applications. They can be easily integrated into existing pipeline systems, offering flexibility in design and installation.

4. Cost-Effectiveness Compared to other materials like bronze or stainless steel, ductile iron offers a more economical solution without compromising on strength or reliability. This affordability makes it a popular choice for many industries looking to optimize their operational costs.

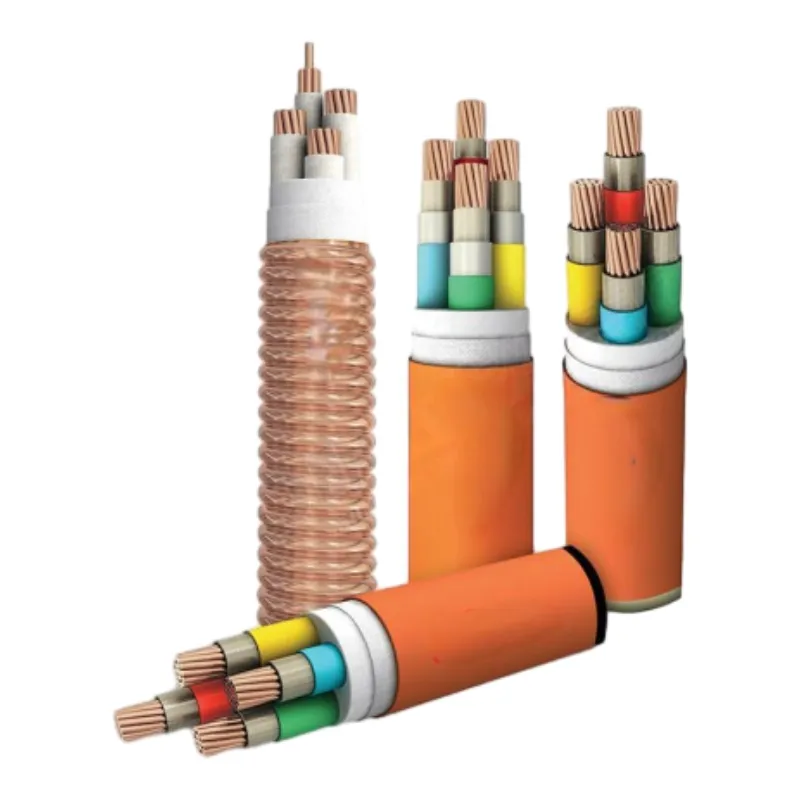

ductile iron check valve

Functionality of Check Valves

Check valves are designed to allow fluid to flow in one direction while preventing backflow. In ductile iron check valves, this is achieved through a mechanical disc that opens and closes based on the pressure differential between the upstream and downstream sides. When the fluid flows in the intended direction, the pressure is sufficient to lift the disc, allowing flow. However, if the flow reverses, the pressure drops, and the disc closes tightly to prevent backflow, thus protecting downstream systems from contamination and pressure surges.

Applications Across Industries

Ductile iron check valves are utilized across a wide variety of sectors

- Water Supply Systems In municipal water supply and sewage systems, these valves are essential for preventing backflow, thereby maintaining water quality and system integrity. - Oil and Gas The petroleum industry relies on ductile iron check valves to protect pipelines and processing equipment from potential damage caused by backflow during pipeline shutdowns or maintenance. - Chemical Processing In chemical manufacturing, these check valves help ensure safe fluid movement, minimizing the risk of cross-contamination between different chemicals.

Conclusion

Ductile iron check valves offer an optimal combination of strength, durability, and cost-effectiveness, making them a preferred choice in many industrial applications. Their ability to withstand harsh conditions while providing reliable backflow prevention is invaluable. As industries continue to evolve, the demand for robust and effective fluid management solutions, such as ductile iron check valves, will likely increase, ensuring the continued relevance and importance of these essential components in modern infrastructure.

In summary, whether for municipal applications or industrial uses, ductile iron check valves stand out as a reliable and efficient solution for maintaining the integrity of fluid systems.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024