9 月 . 24, 2024 18:55 Back to list

Durable Ductile Iron Butterfly Valve for Reliable Flow Control Solutions

The Ductile Iron Butterfly Valve A Key Component in Fluid Control

In various industrial applications, the efficient control of fluid flow is crucial. One of the most effective devices for achieving this is the butterfly valve, particularly those constructed from ductile iron. This article will explore the features, advantages, and applications of ductile iron butterfly valves, highlighting their significance in modern fluid management systems.

What is a Butterfly Valve?

A butterfly valve is a type of quarter-turn valve that uses a rotating disc to regulate flow. When the valve is closed, the disc is perpendicular to the flow of the fluid, presenting a barrier that stops flow. When opened, the disc aligns parallel to the pipe, allowing fluid to flow freely. The simplicity of its design enables rapid operation, making butterfly valves ideal for systems requiring quick shut-off and control.

Ductile Iron A Superior Material

Ductile iron, also known as ductile cast iron or spheroidal graphite iron, is a material that offers significant advantages over traditional cast iron. Ductile iron is produced by adding a small amount of magnesium to molten iron, resulting in a structure that gives it greater tensile strength and ductility. This makes it less brittle and more resistant to deformation under stress, contributing to its popularity in various industrial applications.

Advantages of Ductile Iron Butterfly Valves

1. Strength and Durability Ductile iron's high strength-to-weight ratio ensures that butterfly valves can withstand high pressures and harsh operating conditions. They can endure extreme temperatures and resist corrosion, making them suitable for diverse applications, from water treatment to oil and gas.

2. Lightweight Design Compared to traditional materials, ductile iron is lighter while maintaining strength. This characteristic simplifies installation and reduces the need for heavy lifting equipment, thereby cutting down labor costs and time.

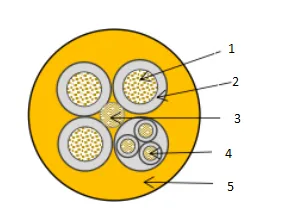

ductile iron butterfly valve

3. Cost-Effective The durability and longevity of ductile iron butterfly valves result in lower maintenance costs over time. Their ability to operate reliably in demanding environments makes them a cost-effective choice for industries that require frequent valve operation.

4. Versatility Ductile iron butterfly valves are available in a range of sizes and configurations, making them suitable for various applications, including HVAC systems, water supply networks, and wastewater treatment facilities. They can handle different media, including liquids and gases, providing flexibility in application.

5. Ease of Operation The quarter-turn operation of butterfly valves allows for quick and efficient control of fluid flow. This responsiveness is particularly beneficial in emergency shut-off situations, where rapid action is needed to prevent accidents or equipment damage.

6. Sealing Performance Advanced sealing technologies, such as resilient seat designs, ensure that ductile iron butterfly valves provide an excellent barrier against leakage. This feature is critical in applications where controlling the flow of hazardous or expensive fluids is necessary.

Applications of Ductile Iron Butterfly Valves

Ductile iron butterfly valves are used across a range of industries. In water and wastewater treatment facilities, they play a vital role in controlling the flow of water and the treatment processes. In the oil and gas sector, these valves help manage the flow of hydrocarbons under high pressure. They are also commonly found in HVAC systems, power generation plants, and even food processing facilities, demonstrating their versatility and reliability.

Conclusion

In conclusion, ductile iron butterfly valves are an essential component in the fluid control systems of numerous industries. Their strength, lightweight design, cost-effectiveness, and excellent sealing performance make them a preferred choice for engineers and operators alike. As industries continue to seek efficient and durable solutions for fluid management, the role of ductile iron butterfly valves will undoubtedly remain significant, contributing to the safe and effective operation of diverse processes worldwide. As technology advances, we can expect to see further innovations in the design and functionality of these critical components, ensuring they continue to meet the evolving demands of the industry.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024