10 月 . 20, 2024 16:14 Back to list

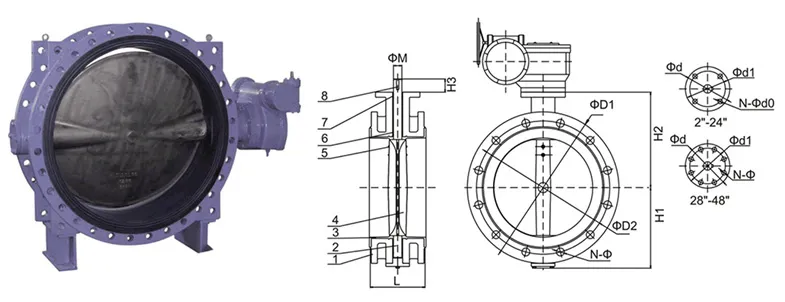

ductile iron butterfly valve

Ductile Iron Butterfly Valves An Overview of Their Features and Advantages

Ductile iron butterfly valves are a critical component used in various industries for controlling the flow of fluids in pipelines. Renowned for their durability, strength, and flexibility, these valves have become a preferred choice for many applications, ranging from water and wastewater management to oil and gas production. This article will explore the key characteristics, benefits, and applications of ductile iron butterfly valves.

Material Characteristics

Ductile iron, also known as spheroidal graphite iron, is notable for its remarkable physical properties, which include high tensile strength, ductility, and resistance to impact and corrosion. The unique microstructure of ductile iron allows it to withstand high pressures and extreme temperatures, making it an ideal material for butterfly valves. This ensures that the valves can operate effectively in demanding environments without premature wear or failure.

The addition of alloying elements such as copper, nickel, and molybdenum can enhance the performance of ductile iron butterfly valves further, enabling them to withstand harsh conditions and extend their service life. Furthermore, the manufacturing process of ductile iron allows for intricate designs, giving engineers the flexibility to tailor valves to specific operational requirements.

Design and Operation

Butterfly valves operate using a simple yet effective mechanism. A rotating disc, which is the valve's governing body, is positioned in the center of the pipe. When the handle or actuator is turned, the disc rotates either 90 degrees to open the valve fully or close it completely—allowing for quick and efficient flow control. This design is not only space-efficient but also facilitates easy installation, maintenance, and operation, making ductile iron butterfly valves a practical solution in various settings.

One of the key design features is the sealing mechanism. Ductile iron butterfly valves can be equipped with different types of seals, including elastomeric or metal seals, depending on the application needs. This adaptability ensures that the valves can achieve tight sealing and prevent leakage, contributing to environmental safety and operational efficiency.

ductile iron butterfly valve

Benefits of Ductile Iron Butterfly Valves

1. Durability The inherent strength of ductile iron materials ensures that these valves withstand wear and tear over time. Their resistance to corrosion and high-temperature environments also enhances their longevity, reducing replacement frequency and associated costs.

2. Versatile Applications Ductile iron butterfly valves can be employed across a wide array of industries, including municipal water systems, chemical processing, HVAC systems, and food and beverage manufacturing. Their versatility extends to different media types, such as gas, liquid, and slurry.

3. Cost-Effective While the initial investment in ductile iron butterfly valves might be higher than other materials, their durability and low maintenance needs make them a cost-effective choice in the long run. Reduced downtime and fewer replacements contribute to significant savings over time.

4. Flow Control Efficiency The design of butterfly valves allows for minimal pressure drops across the valve, which helps in maintaining system efficiency. Furthermore, their quick operation leads to added efficiency in system management, crucial for process control.

Conclusion

In summary, ductile iron butterfly valves stand out as a robust and versatile component in industrial fluid control systems. Their unique material properties, efficient design, and long-lasting performance make them an excellent choice across numerous applications. As industries continue to seek cost-effective and reliable solutions for fluid control, ductile iron butterfly valves are well-poised to remain a staple in engineering practice. Investing in quality ductile iron butterfly valves means investing in reliability, efficiency, and enhanced operational longevity—key factors that are essential in today’s fast-paced industrial landscape.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024