10 月 . 04, 2024 23:06 Back to list

Wafer Style Dual Plate Check Valve Overview and Specifications

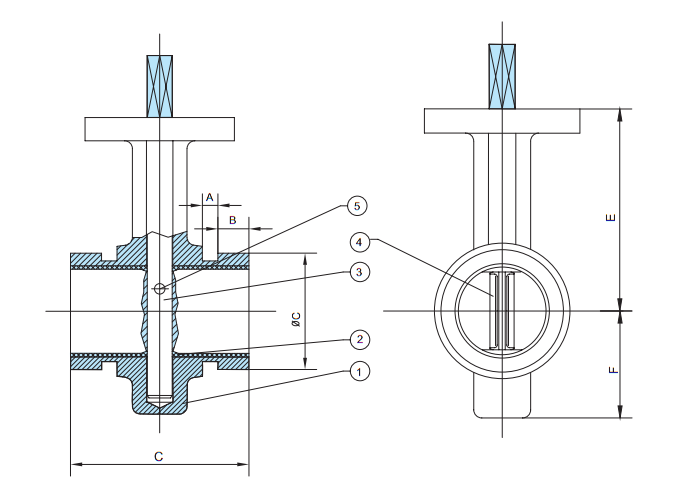

Understanding the Dual Plate Check Valve Wafer Type

The dual plate check valve, particularly in its wafer type, is an essential component in various fluid systems, ensuring unidirectional flow while preventing backflow. This valve design is widely appreciated in industries such as water treatment, oil and gas, and HVAC systems due to its efficiency and compact nature.

Design and Functionality

The dual plate check valve features two spring-loaded plates that open and close in response to fluid flow. Unlike traditional swing check valves, which use a single disc that pivots on a hinge, the dual plate design allows for a more streamlined operation. The plates work by detecting fluid movement; when the flow direction is normal, the plates open, allowing fluid to pass through. Conversely, if the flow reverses, the plates close swiftly, preventing backflow. This swift action minimizes water hammer effects, thus enhancing system stability.

The wafer type design presents a compact and lightweight alternative to other valve types. This configuration eliminates the need for extensive flanges or fittings, allowing the valve to fit directly between the piping flanges. Such a design not only saves space but also reduces installation costs and time.

Key Advantages

1. Space Efficiency The wafer type dual plate check valve is notably thinner than conventional valves, making it suitable for applications where space is a premium. Its compact design is especially beneficial in retrofitting existing systems.

dual plate check valve wafer type

2. Low Pressure Loss Due to the streamlined flow path created by its unique design, the dual plate check valve experiences lower pressure drops. This efficiency translates to energy savings and improved operational performance in fluid systems.

3. Durability and Reliability These valves are often made from robust materials such as stainless steel, making them resistant to corrosive environments. The dual plate mechanism also reduces the chances of wear and tear, ensuring longevity and reduced maintenance requirements.

4. Versatility Dual plate check valves can be employed in various applications, from municipal water pipelines to industrial processes, showcasing their adaptability across different environments and needs.

Applications

The versatility of the dual plate check valve allows it to serve multiple industries. In water treatment plants, it prevents contaminants from entering the supply due to backflow. In oil and gas applications, it ensures the safety and consistency of flow in pipelines. HVAC systems utilize these valves to maintain system pressure and prevent reverse flow, optimizing operational efficiency.

Conclusion

In summary, the dual plate check valve in wafer type form is a critical element in modern fluid management systems. Its unique design offers a plethora of advantages, including space saving, low pressure loss, durability, and versatility across various applications. As industries continue to prioritize efficiency and reliability, the demand for dual plate check valves is likely to grow, making them a significant player in the engineering and fluid dynamics sectors. Understanding and utilizing these valves can lead to significant improvements in system performance and operational reliability.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024