10 月 . 12, 2024 10:52 Back to list

Dual Flap Check Valve Design and Applications for Efficient Fluid Control

Understanding Dual Flap Check Valves Functionality, Applications, and Benefits

Check valves are essential components in various fluid systems, designed to prevent backflow and ensure unidirectional flow. Among the different types of check valves, dual flap check valves have gained prominence due to their efficiency and reliability. In this article, we will explore the functionality, applications, and benefits of dual flap check valves, shedding light on why they are a preferred choice in many industries.

Functionality of Dual Flap Check Valves

Dual flap check valves, also known as dual-plate check valves, consist of two flaps that are hinged at the top and are capable of closing quickly when there is reverse flow. This design allows the valve to effectively seal off the pipeline when the flow direction changes, preventing any potential leakage back into the system. The flaps are usually made from materials that offer high resistance to corrosion and wear, ensuring a long service life.

The operational mechanism of dual flap check valves is straightforward yet highly effective. When the fluid flows in the desired direction, the pressure pushes the flaps open, allowing unrestricted flow. As soon as the forward flow decreases or a reverse flow is detected, the flaps close swiftly, minimizing the risk of backflow. This design not only enhances the performance of the fluid system but also helps in maintaining the overall integrity of the system.

Applications of Dual Flap Check Valves

Dual flap check valves are utilized across various industries due to their versatility and reliability. Common applications include

1. Water and Wastewater Treatment These valves are crucial in water treatment plants, where they prevent backflow in pipelines carrying treated water or wastewater. They help maintain the efficiency of the system and protect the quality of treated water.

2. Oil and Gas In the oil and gas industry, dual flap check valves play a vital role in ensuring that crude oil and natural gas flow in one direction. Their ability to handle high pressure makes them ideal for upstream and downstream applications.

3. Power Generation Power plants use dual flap check valves in their cooling water systems. These valves prevent reverse flow, ensuring that the cooling systems operate efficiently and safely.

4. Chemical Processing In the chemical industry, these valves assist in controlling the flow of various chemicals, preventing contamination and ensuring safe operations.

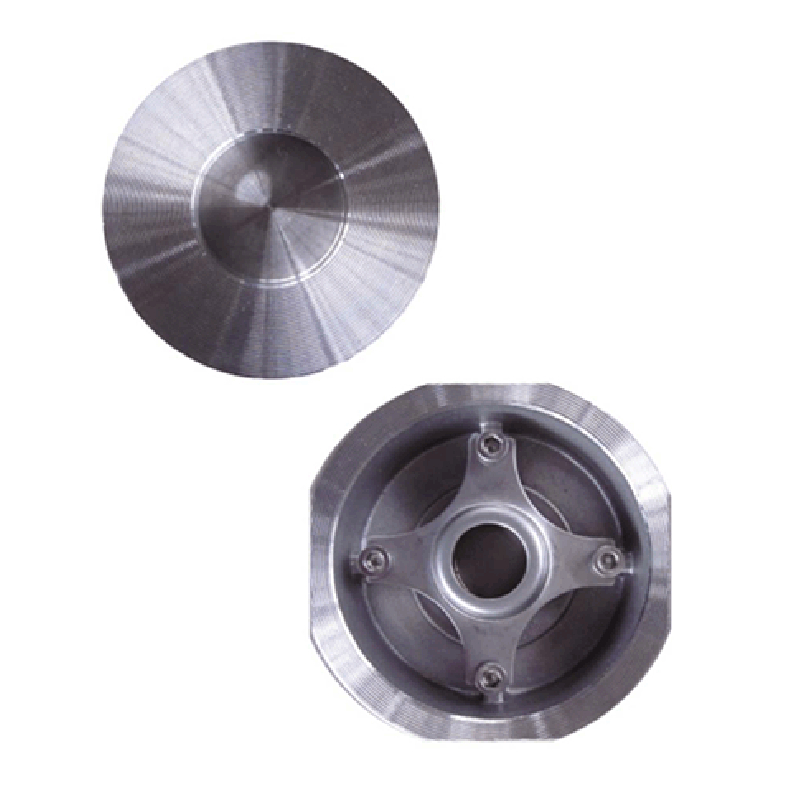

dual flap check valve

5. HVAC Systems The integration of dual flap check valves in heating, ventilation, and air conditioning systems helps maintain airflow direction, improving the efficiency of the entire system.

Benefits of Dual Flap Check Valves

The adoption of dual flap check valves comes with several advantages

1. Efficient Flow Control They provide reliable sealing capabilities, ensuring that backflow is effectively eliminated. This efficiency enhances the overall performance of fluid systems.

2. Reduced Maintenance The design and materials used in dual flap check valves lead to reduced wear and tear, resulting in lower maintenance requirements and longer service life.

3. Compact Design With a relatively lightweight and compact design, dual flap check valves can be easily installed in various locations within a system, making them suitable for both new constructions and retrofits.

4. Cost-Effective Given their durability and minimal maintenance needs, dual flap check valves can be a cost-effective solution in the long term.

5. Versatility Their ability to handle various fluids, including corrosive and viscous substances, makes them suitable for a wide range of applications across multiple industries.

Conclusion

Dual flap check valves represent a critical component in modern fluid systems, offering a reliable solution for preventing backflow and maintaining unidirectional flow. Their functionality, diverse applications, and numerous benefits make them a preferred choice in industries ranging from water treatment to oil and gas. As industries continue to advance, the demand for efficient and reliable components like dual flap check valves will only increase, ensuring that these valuable devices remain at the forefront of fluid management solutions.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024