9 月 . 22, 2024 15:59 Back to list

double sphere union type rubber joint

Understanding Double Sphere Union Type Rubber Joints

In the realm of mechanical engineering and piping systems, rubber joints play a crucial role in facilitating connections and ensuring the smooth operation of various systems

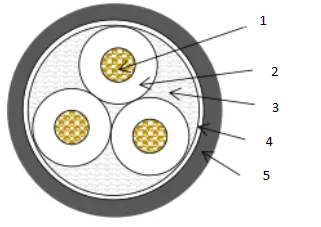

. Among the different types of rubber joints available, the double sphere union type rubber joint stands out for its unique design and versatile applications.A double sphere union type rubber joint consists of two spherical ends joined by a flexible rubber section. This design allows for rotational movement and the ability to absorb vibrations and shocks during operation, making it ideal for dynamic environments where pipes and machinery are subject to frequent movement or settlement. The spherical ends are typically made from durable materials and are fitted with flanges or other attachment methods, ensuring a secure and leak-free connection.

One of the most significant advantages of this type of rubber joint is its ability to accommodate misalignment. In piping systems, it is not uncommon for pipes to be installed at slight angles or to experience thermal expansion and contraction. The double sphere design allows for angular deflection, which helps to maintain the integrity of the system and prevents undue stress on the connected pipes. This feature is particularly vital in industries where precision and durability are paramount, such as in water treatment plants, chemical processing facilities, and HVAC systems.

double sphere union type rubber joint

Moreover, the material used in double sphere union rubber joints is typically resistant to various environmental factors. They can withstand exposure to chemicals, oils, and UV radiation, making them suitable for both indoor and outdoor applications. This resilience extends the lifespan of the joint and minimizes the need for frequent replacements, ultimately resulting in cost savings for businesses.

Installation of double sphere rubber joints is relatively straightforward, which is another reason for their widespread use. Technicians can easily align the joint with existing pipes and securely fasten it, ensuring a quick and efficient setup. Additionally, the flexibility of the rubber material allows for easy adjustments during installation, further accommodating any minor discrepancies in alignment.

In summary, double sphere union type rubber joints are an essential component in various industrial applications due to their flexibility, durability, and ability to absorb shocks and vibrations. Their unique design allows for misalignment accommodation, making them suitable for dynamic systems where movement is prevalent. With resistance to environmental factors and straightforward installation, these rubber joints provide an effective solution for maintaining the integrity of piping systems across multiple industries. As the demand for reliable and efficient mechanical connections continues to grow, the importance of double sphere union type rubber joints will undoubtedly remain significant in the engineering landscape.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024