2 月 . 14, 2025 11:53 Back to list

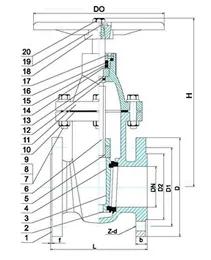

double sphere flange type rubber joint

The double sphere flange type rubber joint is a pivotal component in modern piping systems, renowned for its superior ability to absorb vibrations, compensate for misalignments, and reduce noise transmission within various industrial applications. As industries continue to prioritize operational efficiency and safety, the demand for high-quality rubber joints that exemplify performance reliability and durability has surged.

Moreover, expert feedback from industrial operations has consistently highlighted their pivotal role in extending the lifespan of associated piping systems. By effectively mitigating the transmission of pump pulsations and mechanical vibrations, these rubber joints preserve the integrity of connected components, reducing the need for frequent maintenance and replacement. Such protective properties are integral in highly sensitive operations, such as chemical processing or HVAC systems, where any downtime can translate into significant operational interruptions and financial loss. Trust in the double sphere flange type rubber joint is reinforced by its extensive application across diverse sectors. From manufacturing units to municipal infrastructure, their deployment in both small scale and massive pipeline networks underscores their proven reliability and cost-effectiveness. Professionals within these fields advocate for their use, not solely based on their ability to enhance operational dynamics but also due to their contribution toward optimizing overall project costs. By minimizing maintenance interventions and enhancing system longevity, these joints offer a tangible return on investment. In summary, the double sphere flange type rubber joint is an embodiment of engineering innovation, marrying material science with practical application. Its unique design and superior material composition cater to modern-day requirements for durable, efficient, and trustworthy pipeline components. For businesses aiming to uphold the highest standards of operational excellence and safety, investing in these rubber joints is a strategic decision that aligns with sustainable and cost-effective industrial practices. Whether in new developments or existing systems, their role is indisputable, securing their place as a critical asset in the infrastructure of the future.

Moreover, expert feedback from industrial operations has consistently highlighted their pivotal role in extending the lifespan of associated piping systems. By effectively mitigating the transmission of pump pulsations and mechanical vibrations, these rubber joints preserve the integrity of connected components, reducing the need for frequent maintenance and replacement. Such protective properties are integral in highly sensitive operations, such as chemical processing or HVAC systems, where any downtime can translate into significant operational interruptions and financial loss. Trust in the double sphere flange type rubber joint is reinforced by its extensive application across diverse sectors. From manufacturing units to municipal infrastructure, their deployment in both small scale and massive pipeline networks underscores their proven reliability and cost-effectiveness. Professionals within these fields advocate for their use, not solely based on their ability to enhance operational dynamics but also due to their contribution toward optimizing overall project costs. By minimizing maintenance interventions and enhancing system longevity, these joints offer a tangible return on investment. In summary, the double sphere flange type rubber joint is an embodiment of engineering innovation, marrying material science with practical application. Its unique design and superior material composition cater to modern-day requirements for durable, efficient, and trustworthy pipeline components. For businesses aiming to uphold the highest standards of operational excellence and safety, investing in these rubber joints is a strategic decision that aligns with sustainable and cost-effective industrial practices. Whether in new developments or existing systems, their role is indisputable, securing their place as a critical asset in the infrastructure of the future.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024