10 月 . 12, 2024 18:00 Back to list

double plate check valve

Understanding Double Plate Check Valves An Essential Component in Fluid Systems

In the realm of fluid control, valves play a crucial role in regulating the flow of liquids and gases through a system. Among the various types of valves available, the double plate check valve stands out due to its unique design and functionality. This article delves into the structure, working principle, benefits, and applications of double plate check valves, shedding light on why they are essential components in numerous industries.

What is a Double Plate Check Valve?

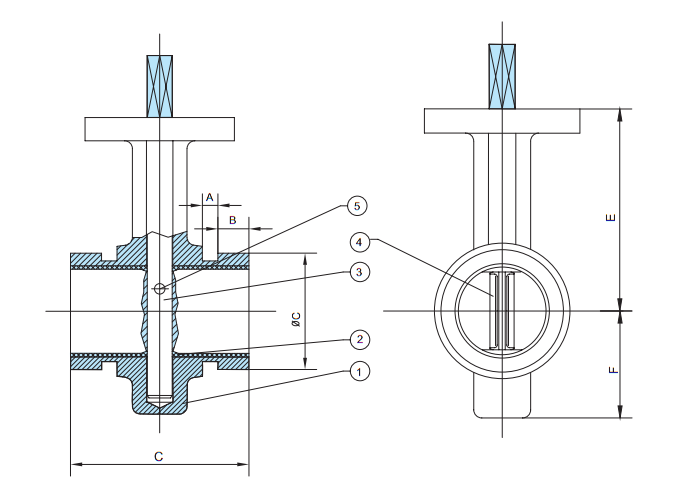

A double plate check valve, also known as a wafer check valve, is a type of non-return valve that allows fluid to flow in one direction while preventing backflow. Its design comprises two plates (or discs) that pivot on a central hinge point. When fluid flows forward, the plates open to allow passage. Conversely, if the flow reverses, the plates close to seal off the flow, protecting the system from potential damage caused by backflow.

Working Principle

The operation of a double plate check valve is straightforward yet efficient. As fluid enters the valve, it exerts pressure on the plates, pushing them apart and enabling the flow to continue. The angle of the plates allows them to move freely, creating minimal resistance to the forward flow. However, once the forward flow diminishes or reverses, the weight of the plates, along with the backpressure of the fluid, causes them to close quickly. This rapid closure aids in preventing water hammer—a common issue that can lead to costly damages within piping systems.

Benefits of Double Plate Check Valves

One of the primary advantages of double plate check valves is their compact design. Unlike traditional swing check valves that require additional space for operation, double plate check valves are much more streamlined, making them ideal for installations with space constraints. This compactness also contributes to a lighter weight, reducing the overall load on the pipeline structure.

double plate check valve

Another significant benefit is their efficient sealing ability. The unique design of the double plate mechanism ensures a tight seal, minimizing the risk of leakage. Additionally, the quick closure feature not only prevents backflow but also reduces the risk of water hammer, enhancing the longevity of associated equipment.

Moreover, double plate check valves exhibit versatility in various applications. They are widely used in water and wastewater treatment plants, industrial processes, and HVAC systems. Their capability to handle a variety of flow media, including water, oil, gas, and other fluids, further emphasizes their adaptability in diverse operational conditions.

Applications

The applications of double plate check valves are extensive. In water supply and irrigation systems, these valves ensure that water flows in the correct direction, safeguarding pumps and other infrastructure from the damaging effects of backflow. In the oil and gas industry, they are utilized to maintain pressure in pipelines, preventing backflow that could lead to leakages or even catastrophic failures.

Moreover, in HVAC systems, they are employed to regulate the flow of refrigerants, ensuring that systems operate efficiently without the risk of reverse flow. Their reliability and efficiency make them a staple in any system where fluid control is paramount.

Conclusion

In conclusion, double plate check valves are vital components in fluid control systems, providing a reliable means of preventing backflow while occupying minimal space. Their design offers numerous advantages, including efficient operation, quick sealing action, and versatility across various industries. As industries continue to evolve, the importance of robust and reliable valves, such as the double plate check valve, will undoubtedly remain at the forefront of fluid management solutions.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024