10 月 . 07, 2024 11:27 Back to list

double plate check valve

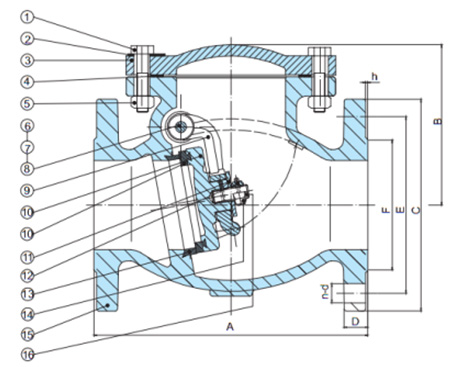

Understanding Double Plate Check Valves A Comprehensive Overview

Double plate check valves are essential components in fluid carrying systems, recognized for their ability to prevent backflow while minimizing pressure loss. These innovative devices are designed to improve the efficiency of pipelines, making them invaluable in various applications, including water supply, wastewater treatment, and industrial processes.

The primary function of a double plate check valve is to allow fluid to flow in one direction while blocking it from reversing. This is particularly important in systems where backflow can lead to contamination or system damage. The double plate mechanism consists of two spring-loaded plates that open when fluid flows in the correct direction. When the fluid attempts to flow backward, the plates close tightly, thanks to the inherent spring tension. This design provides a reliable seal, significantly reducing the risk of leakage.

One of the key advantages of double plate check valves is their low-pressure drop. Unlike traditional swing check valves, which can cause significant turbulence when fluid flows through, double plate valves present a streamlined profile. This design feature allows them to operate efficiently, providing minimal resistance to flow. Consequently, they can contribute to energy savings in systems where pumps are used to move fluids.

double plate check valve

Materials used in the construction of double plate check valves are varied and tailored to specific applications. Common materials include stainless steel, ductile iron, and bronze, each selected for their durability, corrosion resistance, and suitability for different environmental conditions. The choice of material directly impacts the valve's performance and longevity, making it essential for engineers to consider the specific conditions under which the valve will operate.

Installation and maintenance of double plate check valves are crucial for ensuring long-term reliability. These valves can be installed in both vertical and horizontal orientations, providing flexibility in design and implementation. Regular maintenance is, however, recommended to ensure the springs and plates are functioning correctly and to prevent blockages due to debris accumulation.

In summary, double plate check valves offer a combination of efficient fluid handling and robust backflow prevention. Their design minimizes pressure loss and enhances the overall efficiency of piping systems. As industries continue to advance and place greater emphasis on sustainability and efficiency, the role of double plate check valves will undoubtedly become more significant. With their reliable operation and versatility, these check valves are integral to the success of modern fluid management systems. Whether in municipal water supplies or industrial applications, understanding their functionality and proper application is key to optimizing system performance and ensuring safety.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024