9 月 . 23, 2024 04:40 Back to list

double plate check valve

Understanding Double Plate Check Valves An Essential Component in Fluid Control Systems

In various industries, the need for efficient fluid control systems is paramount. One of the critical components that ensure the seamless flow of liquids and gases while preventing backflow is the double plate check valve. This valve design has gained popularity due to its efficiency, reliability, and compact size, making it an essential part of many piping systems.

What is a Double Plate Check Valve?

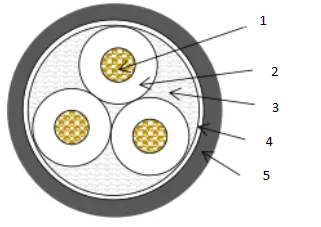

A double plate check valve is a type of non-return valve that features two symmetrically positioned plates. These plates are hinged at the top, allowing them to open and close based on the direction of fluid flow. When fluid flows in the forward direction, the plates swing open, permitting the flow. Conversely, if the flow stops or reverses, the plates automatically close, preventing backflow. This mechanism is crucial in protecting equipment, preventing contamination, and maintaining system integrity.

Advantages of Double Plate Check Valves

1. Compact Design Compared to traditional check valves, the double plate design is significantly more compact, allowing for easier installation in tight spaces. This feature makes it an ideal choice for various applications, including plumbing, HVAC systems, and industrial pipelines.

2. Reduced Pressure Drop The streamlined design of the double plates minimizes turbulence and resistance in the flow path, resulting in a lower pressure drop across the valve. This efficiency helps in conserving energy and ensuring optimal system performance.

double plate check valve

3. Quick Response Time The lightweight plates of a double plate check valve allow for rapid opening and closing. This quick response is essential in systems where fluid dynamics can change suddenly, such as in pumping applications.

4. Durability and Maintenance These valves are built to withstand harsh conditions thanks to materials like stainless steel, ductile iron, or bronze. Their simple design also means that there are fewer components that can wear out, resulting in lower maintenance requirements and prolonged service life.

Applications

Double plate check valves are widely used in various applications, including water and wastewater treatment, oil and gas, power generation, and fire protection systems. Their ability to prevent backflow makes them essential for maintaining the safety and efficiency of these systems.

Conclusion

In summary, double plate check valves play a crucial role in fluid control systems across several industries. Their compact design, minimal pressure drop, and durability make them a preferred choice for engineers and operators. As industries continue to emphasize efficiency and safety, the importance of reliable components like double plate check valves cannot be overstated. Investing in quality check valves is not just a matter of compliance; it’s a commitment to operational excellence and system reliability.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024